That has a sound small business credit, great after-sales service and modern production facilities, we’ve earned an outstanding standing amid our buyers across the earth for Factory Selling Pvc Machine Pvc Connection Pipe Production Line, Special emphasis on the packaging of products to avoid any damage during transportation,Detailed attention to the valuable feedback and suggestions of our esteemed clients.

That has a sound small business credit, great after-sales service and modern production facilities, we’ve earned an outstanding standing amid our buyers across the earth for Pvc Connection Pipe Production Line, Pvc Pipe 2 Cavity Production Machinery, Pvc Rigid Pipe Making Machine, We’re sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

SPECIFICATIONS:

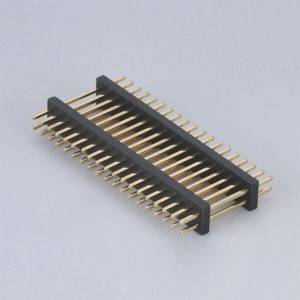

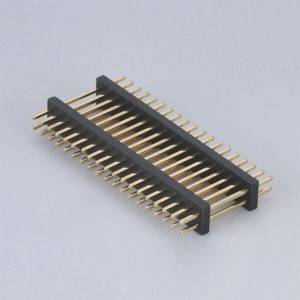

FFC/FPC connector

Pitch:0.5mm(.031″) Mated Height:2.0mm

Push-Pull & Reverse Foot Type

Vertical Surface Mount ZIF

Contacts: 8-60Pin

Category:PCB Headers

Packing:Reel

Compliant with:ROHS & REACH

Electrical & Physical

Current Rating: 0.5 A AC/DC

Voltage Rating:30V AC/DC

Color:Beige and Black

Flammability:UL94V-0

Plating:Tin Plating

Contact Material:Copper Alloy

Housing and Cover:High-Tem Plastic

Operating Temperature: -40℃ ~ +85℃

————————— Company style —————————

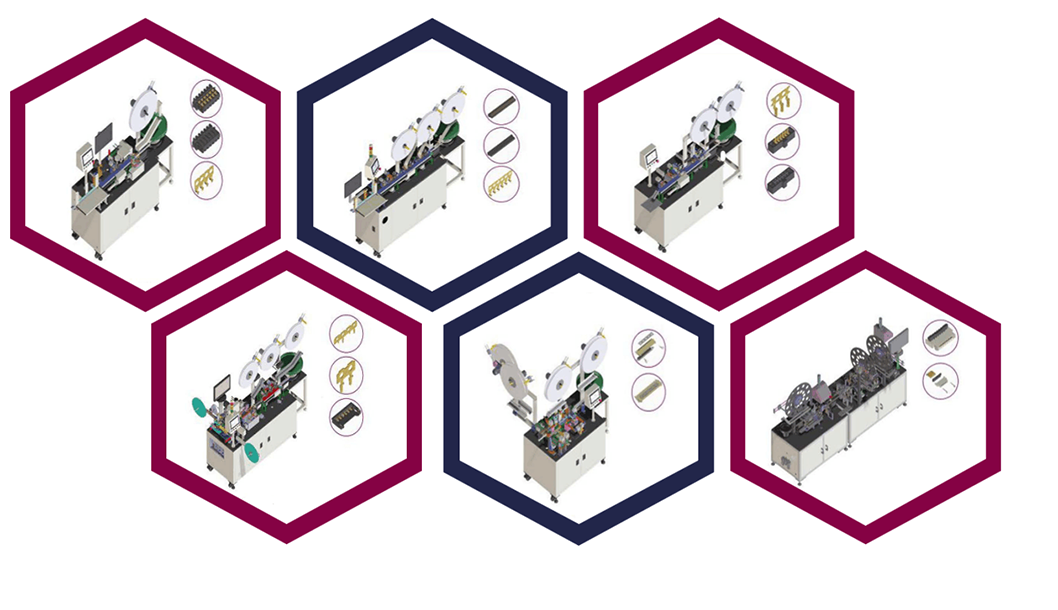

————————— Production line —————————

————————— Production equipment —————————

————————— Injection molding —————————

Injection molding workshop and experienced toolmaker can not only provide customized connector service,but also convenient for daily maintenance and repair of molds, which saves cost and increases efficiency for you. Plastic automatic feeding machine ensured injection sockets have perfect physical parameter. The injection molding machine with take off the mold automatically by mechanical arm improved the efficiency, of which hot runner system ensures the consistency of multi-cavity molding, improves the precision of plastic parts and greatly saves costs.

————————— Connectors —————————

All of our plastic materials are high temperature resistant materials,and most of them are from Taiwan and Japan.Automatic production & inspection & packaging machine guarantee high quality and short lead time. Thanks for automatic machine, our annual output reachs up to 15 million. Furthermore,we were devoted to development and production of alternatives since we founded. A large amount of R&D cost investment and engineer team with over 15 years experiences make us better in the field of small pitch and high precision connectors.

————————— Wire harness & Cable assembly —————————

We assist with cable and connector selection and assembly design solution, layout and manufacturing techniques.Our strength is internal electronic wire harness for various application,like Consumer Electronics,Computing,Medical,Automotive…etc, but more than 200 sets different forming molds can also meet your various need of cable assemblies. Wire cable extruder,automatic terminal crimping machine, digital wire cutting &stripping machine,USB automatic soldering machine,and automatic cable binding machine available to providing one-stop service for you.

Our Advantage :

- Automatic production & inspection & packaging machine ensured high quality and short lead time

- Material from Japan & Taiwan

- Annual Output up to 15 million

- Compliant with ROHS & REACH

- ISO 9001:2015 and IATF16949:2016 certified factory

- Mold workshop and toolmaker with more than 20 years experienced provide customized service

Testing equipment :

We will conduct strict product inspection before shipment.

5.Video Measuring Machine(YVM) 6.360° Degree Rotation Tester 7.Reflow Soldering Tester

5.Video Measuring Machine(YVM) 6.360° Degree Rotation Tester 7.Reflow Soldering Tester

Brine Spray Experiment Machine

High Voltage Tester

Insulation Tester

Contact Resistance Tester

DC Low resistance tester

Mitutoyo Height Gauge

Cable Conduction Tester

HD Coplanarity CCD Tester

Automatic Tester of Insertion And Extraction Force

-

Trending Products Ce Certified Automatic Shortb...

-

Newly Arrival Flexible Connection Pvc Edge Band...

-

Low price for Flexible Connection Extruder Pc M...

-

Quots for Pvc Drain Connection Pipe Making Mach...

-

Fixed Competitive Price Sp13 Screw Install 3 Pi...

-

Factory Cheap Pvc Insulate D Ground Connection ...