Assalamu alaikum, nine editan.A kusan dukkanin samfuran lantarki da na lantarki, masu haɗa allo-da-board sun zama muhimmin abu don haɗa abubuwa daban-daban.Kasancewar mai haɗawa ba don rarrabuwa ba ne kawai da haɗi ba, har ma da mai ɗaukar hoto don samar da halin yanzu da sigina ga samfurin.

A cikin tsarin yin amfani da masu haɗawa, yawancin masu zane-zane na tsarin lantarki sun sami irin wannan kwarewa: yin amfani da masu haɗin kai mai arha, sannan kuma suna biyan farashi mai yawa, har ma da nadama.Zaɓin da ba daidai ba da amfani da masu haɗawa zai iya haifar da gazawar tsarin, tunawa da samfur, shari'o'in abin alhaki na samfur, lalacewar allon kewayawa, sake yin aiki da gyare-gyare, wanda hakan na iya haifar da asarar tallace-tallace da abokan ciniki.Don haka, lokacin zayyana samfuran lantarki, dole ne ku zaɓi mai haɗin da ya dace don na'urar lantarki.In ba haka ba, yanayin da ƙaramin allo-to-board mai haɗawa ya sa tsarin gabaɗaya baya aiki zai ji ya karye sosai.

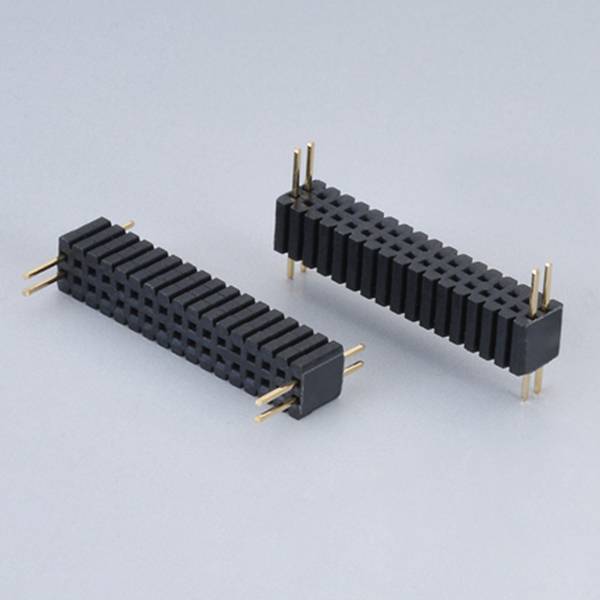

PIN HEADER PITCH:1.0MM(.039″) NAU'IN LAYYA GUDA BIYU

Lokacin da mutane suka zaɓi mai haɗawa, za su fara la'akari da sarrafa farashi.Wasu suna da inganci, babban kwanciyar hankali, da fasalin ƙirar mai haɗin kanta.Don hana masu zanen lantarki yin la'akari da mahimmancin masu haɗawa a cikin tsarin ƙira, saboda ƙananan asara da manyan asara, masana'antun haɗin jirgi na allo suna ba da wasu shawarwari ga kowa da kowa:

Na farko: ra'ayin zanen igiya biyu.A cikin jerin masu haɗin ERNI, ra'ayin ƙirar sandar sandar sandar igiya biyu daidai yake a ko'ina.A bayyane yake, za a iya kwatanta zanen igiya biyu a matsayin "tsuntsaye biyu masu dutse ɗaya".Ingantaccen ƙirar tasha don daidaitawa zuwa watsa sigina mai sauri, yana ba da mafi girman juriya.Dangane da inductance, capacitance, impedance, da dai sauransu, tsarin tashar tashar mashaya biyu ya fi ƙanƙanta fiye da tsarin nau'in akwatin don aikace-aikacen sauri mai sauri kuma an inganta shi don cimma matsananciyar raguwa.Zane-zanen igiya biyu yana ba da damar masu haɗawa da yawa su kasance a kan allon kewayawa ɗaya ba tare da toshewa ko gajerun matsalolin kewaye ba, kuma babu buƙatar yawan adadin sigina akan mai haɗa guda ɗaya.Hanya mai sauƙi na sanduna biyu na iya ajiye sarari, sanya mai haɗawa ya zama ƙarami, da sauƙaƙe gano fil ɗin solder.Misali, sanya 12 a kan allo.Hakanan yana rage farashin sake aiki.Aikace-aikace masu amfani kamar kayan aikin tashar tashar sadarwa, da sauransu.

Na biyu: Tsarin ɗorawa saman saman da ƙarfin riƙewa.Don samfuran SMT, galibi an yi imani da cewa ikon riƙewa a kan jirgin ba shi da kyau.Shin ƙarfin riƙewar PCB na ƙarshen tsaunin saman ƙasa ya fi na ƙarshen ramuka?Amsar ita ce: ba lallai ba ne.Haɓaka ƙira na iya inganta haɓakar PCB yadda ya kamata.Idan madaidaicin madaidaicin, rami (microhole) na fil ɗin dutsen saman, da babban kushin saida, ana iya inganta ƙarfin riƙon.A haƙiƙa, hatta masu haɗin I/O na iya amfani da filaye masu ɗagawa.Ana iya kwatanta wannan a bayyane da "dauko tushen".Misali, a cikin ƙirar na'urorin X-ray, na'urorin daukar hoto na ultrasonic, da na'urorin Ethernet na mutum-mutumi.

Na uku: Tsara mai ƙarfi.Don ƙayyade amincin mai haɗawa, yayin ba da damar yin amfani da kayan aiki na lebur, an kafa farantin igiya a kan harsashi don inganta ƙarfin, don cimma ingantaccen tsarin masana'antu da haɓaka fitarwa.Don taƙaita shi a cikin kalma ɗaya shine "m kamar dutse."Takamaiman aikace-aikace irin su positron emission tomography scanners, tsarin motar motar jirgin ƙasa, da sauransu.

Na hudu: babban halin yanzu, ƙananan ƙirar tazara.Tare da ƙarancin ƙarancin kayan lantarki na kera motoci da na'urorin lantarki na mabukaci, ƙirar ƙira na babban halin yanzu da ƙaramin tazara yana buƙatar la'akari.

Na biyar: Babu ƙira mai lanƙwasa a cikin tsarin taro.Tambarin al'ada zai haifar da lanƙwasa ko nakasar fil saboda aiki mara kyau, kuma tsarin lanƙwasa zai haifar da fashewar capillary, wanda ba a so don samfurin na dogon lokaci, kuma zai shafi aikin kewayawa da farashi.Kuma ERNI tana amfani da tambarin sasanninta kai tsaye, tashoshi na stamping na iya guje wa fashewar capillary wanda tsarin lanƙwasa ya haifar, da tabbatar da cikakkiyar haɗin injin lantarki.Ƙwararren fil ɗin shine 100%, kuma ana sarrafa haƙuri zuwa ± 0.05mm.A 100% surface Dutsen fil coplanarity gwajin tabbatar da amincin da kewaye hukumar taro tsari, tabbatar da kyau soldering, inganta samfurin ingancin kudi, da kuma rage farashin.Kuma inganta ƙarfin haɗin kusurwar dama don hana mai haɗawa daga lalacewa saboda aiki mara kyau.Kalmar "marasa karye" ya dace sosai.Ya dace musamman don ƙirar ƙirar InterfaceModule na mai sarrafa firinta ta inkjet.

Na shida: Ƙirar kulle ta ci gaba.ERNI tana amfani da ƙirar kulle biyu don biyan buƙatu daban-daban.An tsara makullin tabbatacce don aikace-aikacen girgiza mai ƙarfi.Ya dace sosai don aikace-aikacen motoci da jirgin karkashin kasa.An ƙera makullin gogayya don aikace-aikacen jijjiga gabaɗaya.Makulle biyu da inshorar aminci guda biyu suna tabbatar da haɗin gwiwa mai dogaro, kuma ba a buƙatar kayan aiki na musamman don rarrabuwar kan layi (gyara / maye gurbin) na igiyoyi.Ya dace da ƙirar masu saka idanu, fitilun mota na LED, da sauransu.

Masu haɗin jirgi-da-board suna taka muhimmiyar rawa wajen tsara tsarin tsarin lantarki duka.Lokacin zabar kayan aikin lantarki, injiniyoyi suna buƙatar kulawa ba kawai ga fasahar guntu ba, har ma da zaɓin abubuwan da ke kewaye, ta yadda tsarin zai gudana cikin sauƙi., Kunna sakamako mai yawa.

Lokacin aikawa: Satumba-04-2020