Assalamu alaikum, nine editan.Dangane da yanayin kasuwa, masu haɗin jirgi-da-board sun sami babban sauye-sauye a cikin 'yan shekarun nan, kuma masu haɗin jirgi-da-board sun zama ƙarami da ƙarami.Filin haɗin haɗin allo na gama gari na yau da kullun shine 0.40 mm;ko da yake tsayin tari na mm 1 ƙarami ne mai haɗawa, manyan masana'antun aikace-aikacen mahaɗar allo-da-board suna amfani da na'urorin haɗin allo zuwa ƙasa ƙasa da 0.70 mm ko ma ƙasa.Don haka ta yaya za a zaɓi girman haɗin haɗin allo-to-board?Editan mai zuwa yayi bayanin yadda ake zaɓar girman haɗin allo-to-board!

Bayan 'yan shekaru da suka wuce, an maye gurbin tsofaffin masu haɗin daɗaɗɗen da nisa fiye da 4 mm tare da masu haɗin 3.40 mm.Tunanin mai haɗa allo-da-board na yanzu yawanci yana cikin kewayon 2.40 zuwa 2.60 mm.A yayin zabar mai haɗin allo-to-board, ƙarami shine mafi kyau, saboda ƙarami, mafi yawan sararin samaniya zai ƙaru.

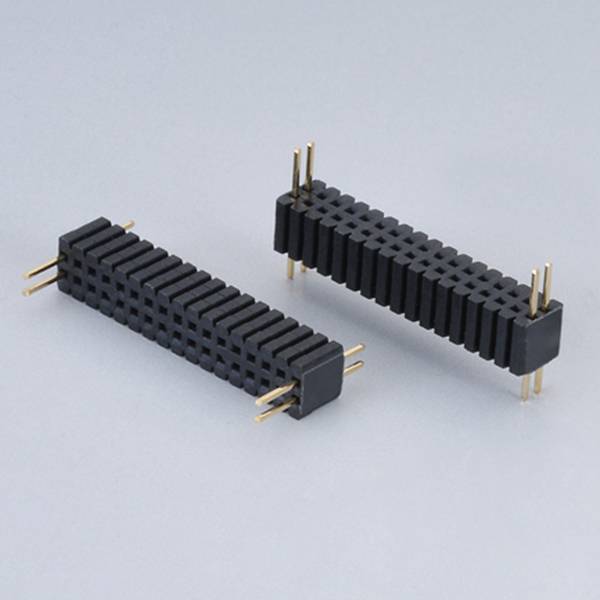

PIN HEADER PITCH:1.0MM(.039″) NAU'IN LAYYA GUDA BIYU

Kafin mu zaɓi yin amfani da mahaɗar ƙaramin allo zuwa allo, muna buƙatar sanin ko mahaɗin yana da duk wasu abubuwan da kuke buƙata, kuma a hankali gwada shi don tabbatar da cewa yana da ƙarfi sosai.Sa'an nan, ana buƙatar soket tare da mahaɗin da aka ɗora a sama saboda ana iya bin wannan saitin a ƙarƙashin soket kuma ana iya amfani da suturar tsari cikin sauƙi.Wasu rashin amfani daga saman-saka soket ne cewa nisa daga cikin injin karba-up wuri ne sau da yawa kunkuntar a kan soket m surface kuma babu wani roba harsashi abu, amma zai iya hana matsala lalacewa ta hanyar m m man fetur a saman saman. soket.

Domin tabbatar da cewa za a iya cire haɗin haɗin allo-da-board ɗin da aka zaɓa cikin sauri, ana iya buƙatar aikin kulle haɗin haɗi na tsawon tsayi don gane mai haɗin allo-da-board na girman da ake buƙata.Kula da ƙarin masu haɗawa don cire haɗin Aiki yawanci yana nufin babban haɗin gwiwa, saboda yana iya haifar da matsala tare da manyan da'irori.

Lokacin aikawa: Satumba-10-2020