Bincike mai zurfi game da matsayin ci gaba na masu haɗin jirgi zuwa jirgi

A halin yanzu, masu haɗin allo-da-board da ake amfani da su akan wayoyin hannu galibi suna da halaye masu zuwa:

Na farko shine "mai sassaucin ra'ayi", haɗin kai mai sassauƙa, da juriya mai ƙarfi;na biyu, babu walda, shigarwa mai dacewa, kuma babu haɗarin wuta, wanda ke adana sarari;amma na yau allon-da-board ne matsananci-low tsawo , Biyu-yanki nau'i, edita zai mayar da hankali a kan wannan batu a kasa;A ƙarshe, yana da juriya na muhalli mai girma, ba kawai sassauƙa ba, amma kuma yana amfani da "haɗi mai ƙarfi" tare da babban amincin lamba;Tabbas, akwai gabaɗaya marasa iyaka da bututu da bel.Abubuwan da ake amfani da su na matsa lamba da shigarwa mai dacewa.

Don haɓaka ƙarfin haɗin gwiwa na soket da filogi, ana amfani da tsarin kulle mai sauƙi a cikin ɓangaren ƙarfe da aka gyara da kuma ɓangaren lamba, wanda ke inganta ƙarfin haɗin gwiwa kuma yana sa kullewa ya fi dacewa.Mai haɗin haɗin zai iya rage kaurin samfurin don cimma manufar haɗin gwiwa, kuma wannan ya haifar da ƙarin ƙananan ƙananan wayoyin hannu a kasuwa!

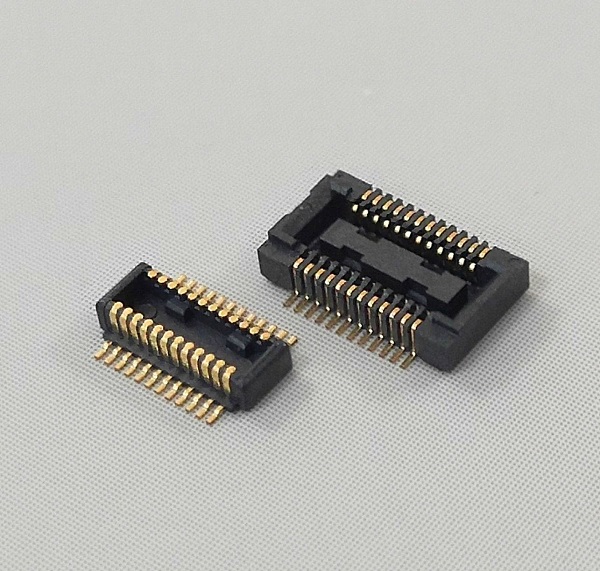

BOARD TO BOARD CONNECTORS PITCH :0.4MM(.016″) SMD H:1.5MM POSITION 10-100PIN

kunkuntar farar allo-to-board connector, 0.35mm farar a halin yanzu ana amfani da shi a cikin wayoyin hannu na Apple da kuma ƙirar gida mai tsayi.Aikace-aikacen sa zai zama babban yanayin a cikin shekaru biyu da suka gabata.Yana da ƙaramin ƙarami, mafi girman daidaici, da babban aiki., Amma abubuwan da ake buƙata don faci da sauran hanyoyin tallafi sun fi girma.Wannan shine inda yawancin masana'antun haɗin haɗin ke buƙatar sabis na abokin ciniki, in ba haka ba yawan amfanin ƙasa zai yi ƙasa sosai.

A yau, lokacin da masu amfani ke da buƙatu mafi girma da mafi girma don kauri samfurin da ƙwarewar ji da hannu, masu haɗaɗɗun bakin ciki da matsananci-ƙunƙutu suna sanya sabbin buƙatu akan tsarin lantarki.Don samfuran da ke da tsayin 0.6mm da samfur guda ɗaya ƙasa da 0.4 mm tsayi, Yadda za a tabbatar da cewa kauri na platin gwal na samfur da tasirin tinning baya hawa kan tin ya zama mafi mahimmancin batun a cikin miniaturization mai haɗawa. .A halin yanzu, al'adar da aka saba yi a masana'antar ita ce toshe hanyar tin na sama ta hanyar bawon ruwan gwal ta hanyar Laser don magance matsalar rashin hawan tin.Duk da haka, wannan fasaha tana da illa ta yadda idan za a cire zinare, Laser kuma zai lalata Layer ɗin da aka yi da nickel, ta yadda za a fallasa tagulla zuwa iska, wanda zai lalata da tsatsa.

Wani abu da za a ambata a yanzu shi ne cewa ana iya gina masu haɗin allo-to-board don ƙirar kewayawar inji mai sauƙi.Ta hanyar shigar da bango mai rufewa a saman ƙasa na mai haɗawa, za a iya karkatar da alamun allon PC da tashoshi na ƙarfe da kuma yin waya a saman ƙasa na mai haɗin ba tare da lamba ba, wanda ke da fa'ida sosai ga ƙaramin allon PC!

Lokacin aikawa: Agusta-28-2020