High Quality for Square Pin Header - Professional China Suction Connection Tube Extruder Line – Yuanyue Detail:

“Quality first, Honesty as base, Sincere service and mutual profit” is our idea, in order to develop continuously and pursue the excellence for Professional China Suction Connection Tube Extruder Line, We glance ahead to supplying you with our goods from the near long run, and you’ll find our quotation is very acceptable plus the top quality of our goods is quite outstanding!

“Quality first, Honesty as base, Sincere service and mutual profit” is our idea, in order to develop continuously and pursue the excellence for Connection Tube Extruder, Suction Connection Tube Extruder Line, Suction Tube Making Line, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we have been not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and supply instant communication. You will instantly feel our expertise and attentive service.

SPECIFICATIONS:

- SPECIFICATIONS:

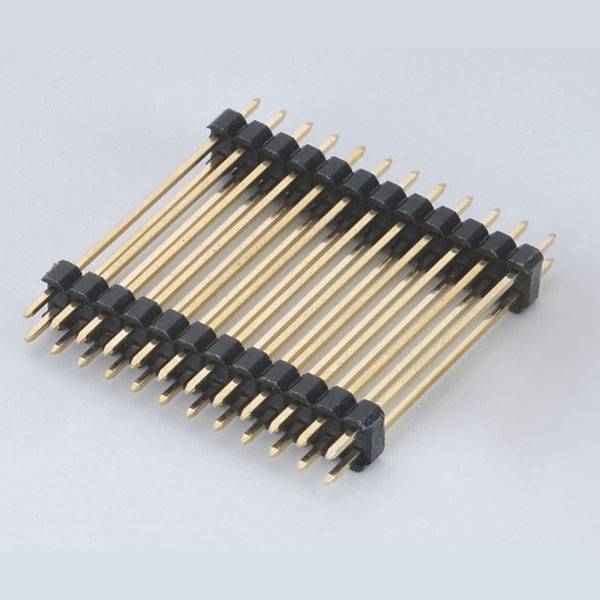

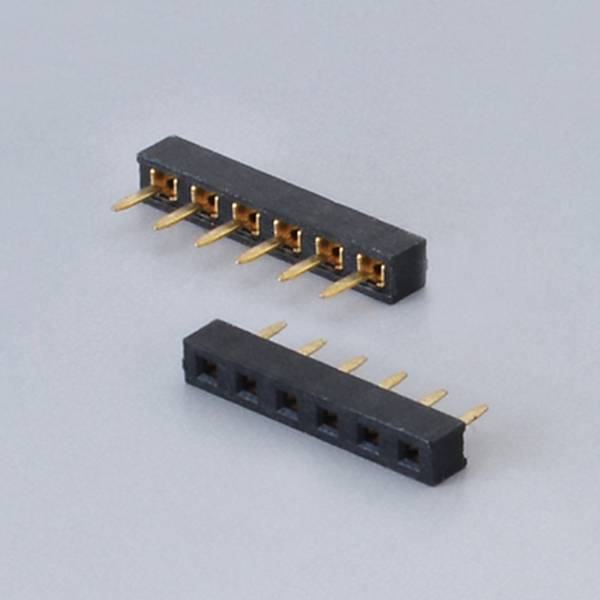

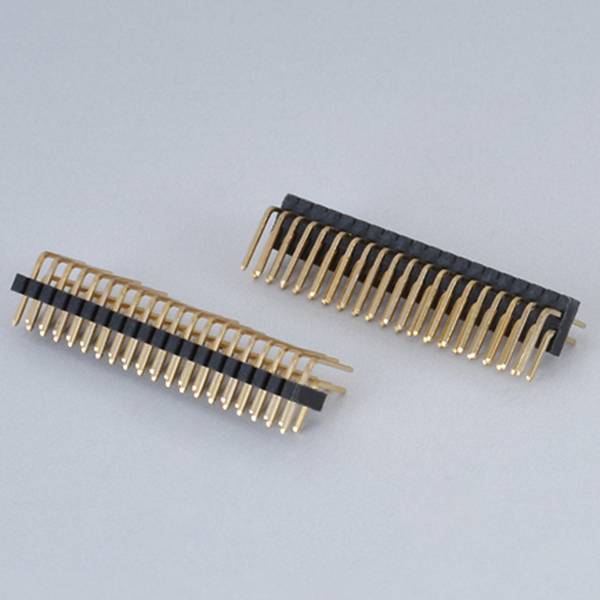

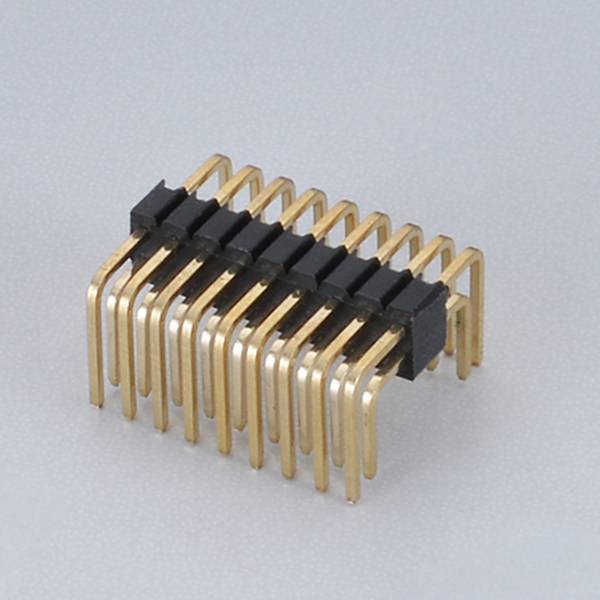

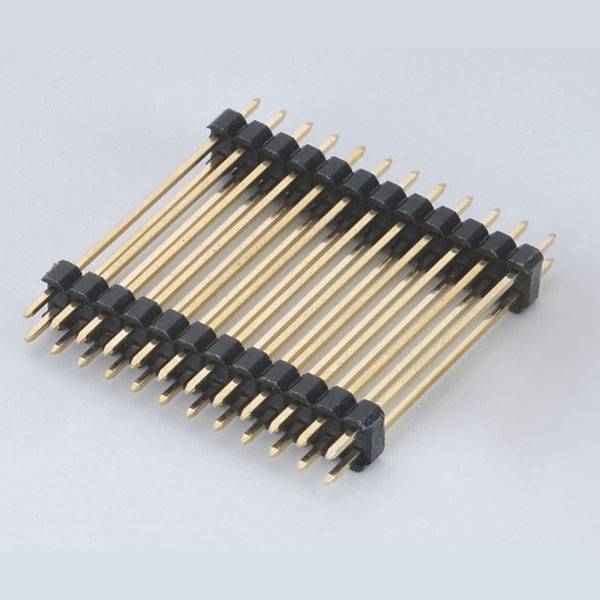

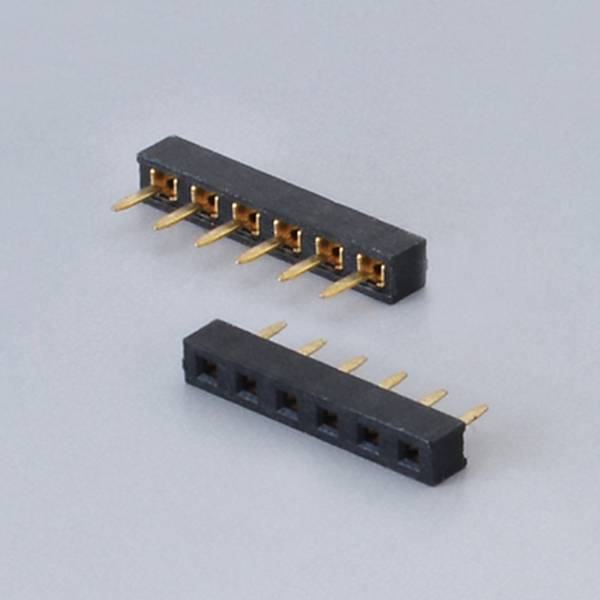

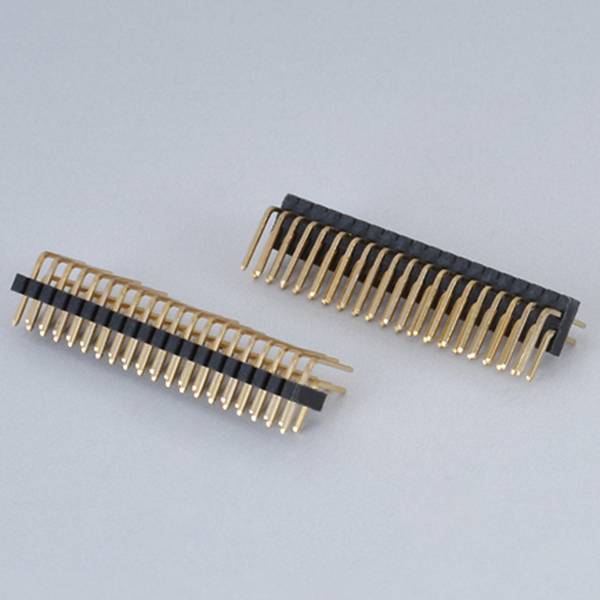

- Pin Male Header

- Pitch:1.27mm(.050″)

- Single Row Right Angle Type

- Position: 01~50Pin

- Category:PCB Headers

- Packing:Bag or Tube

- Compliant with:ROHS & REACH

- Application:Board-to-Board,Wire-to-Board,Signal

Electrical

Current Rating: 1 A AC/DC

Insulation Resistance: 1000 mΩ Min

Withstanding Voltage: 500V AC/DC

Physical

Color:Black

Square Pin:0.4mm(.016″),0.46mm(.018″)

Flammability:UL94V-0

Contact Material:Copper Alloy

Insulator Material:Nylon-6T

Operating Temperature: -40℃ ~ +105℃

soldering temperature:260℃ for 3~5s Max

Optional specifications

Pin Length:Customized

Plastic Height:0.6mm,1.0mm, 1.5mm, 1.6mm, 1.7mm, 2.0mm, 2.54mm

Plastic material:Nylon-6T;Nylon-66;Nylon-9T;LCP

Plating:Tin-plated;Gold Plating

Product detail pictures:

Related Product Guide:

FIFA 19: Pro Clubs Tips And How To Build Your FIFA 19 Pro | Pcb Smt Pin Connector

Aerospace and defense applications drive connector and cabling innovation | Box Headers

High Quality for Square Pin Header - Professional China Suction Connection Tube Extruder Line – Yuanyue, The product will supply to all over the world, such as: , , ,

————————— Company style —————————

————————— Production line —————————

————————— Production equipment —————————

————————— Injection molding —————————

Injection molding workshop and experienced toolmaker can not only provide customized connector service,but also convenient for daily maintenance and repair of molds, which saves cost and increases efficiency for you. Plastic automatic feeding machine ensured injection sockets have perfect physical parameter. The injection molding machine with take off the mold automatically by mechanical arm improved the efficiency, of which hot runner system ensures the consistency of multi-cavity molding, improves the precision of plastic parts and greatly saves costs.

————————— Connectors —————————

All of our plastic materials are high temperature resistant materials,and most of them are from Taiwan and Japan.Automatic production & inspection & packaging machine guarantee high quality and short lead time. Thanks for automatic machine, our annual output reachs up to 15 million. Furthermore,we were devoted to development and production of alternatives since we founded. A large amount of R&D cost investment and engineer team with over 15 years experiences make us better in the field of small pitch and high precision connectors.

————————— Wire harness & Cable assembly —————————

We assist with cable and connector selection and assembly design solution, layout and manufacturing techniques.Our strength is internal electronic wire harness for various application,like Consumer Electronics,Computing,Medical,Automotive…etc, but more than 200 sets different forming molds can also meet your various need of cable assemblies. Wire cable extruder,automatic terminal crimping machine, digital wire cutting &stripping machine,USB automatic soldering machine,and automatic cable binding machine available to providing one-stop service for you.

Our Advantage :

- Automatic production & inspection & packaging machine ensured high quality and short lead time

- Material from Japan & Taiwan

- Annual Output up to 15 million

- Compliant with ROHS & REACH

- ISO 9001:2015 and IATF16949:2016 certified factory

- Mold workshop and toolmaker with more than 20 years experienced provide customized service

Testing equipment :

We will conduct strict product inspection before shipment.

5.Video Measuring Machine(YVM) 6.360° Degree Rotation Tester 7.Reflow Soldering Tester

5.Video Measuring Machine(YVM) 6.360° Degree Rotation Tester 7.Reflow Soldering Tester

Brine Spray Experiment Machine

High Voltage Tester

Insulation Tester

Contact Resistance Tester

DC Low resistance tester

Mitutoyo Height Gauge

Cable Conduction Tester

HD Coplanarity CCD Tester

Automatic Tester of Insertion And Extraction Force

-

Hot sale Factory Bosch Connectors Automotive -...

-

Professional China Plexiglass Suggestion Box -...

-

New Fashion Design for Magnetic Cable Connector...

-

8 Year Exporter Dupont 2.0 Terminal Connector -...

-

Super Lowest Price Rfid Socket Connector - D-S...

-

2017 Good Quality Rj45 Waterproof Connector - ...