1. First of all, “soft”, flexible connection, fast installation, detachable and convenient.

2. The ultra-low height of the board-to-board connector to achieve the purpose of reducing the thickness of the fuselage.

CJT 1.0 board to board connector

3. The contact structure has super environmental resistance, not only flexible, but also selects the “consolidated connection” with high touch reliability to improve the combined force of the socket and the plug. It is easy to select the fixed metal parts and the contact parts. The lock organization, together with the improvement of the combination force, makes the lock punctuality more pluggable.

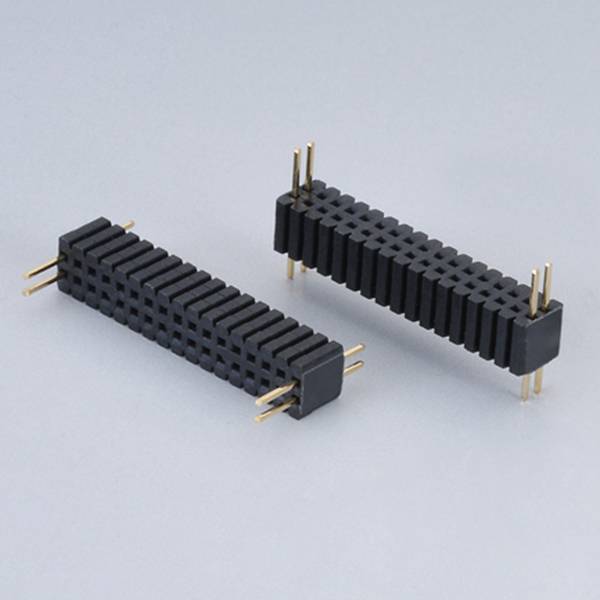

PIN HEADER PITCH:1.0MM(.039″) DUAL ROW STRAIGHT TYPE

4. In order to meet the requirements of the SMT process, the terminal welding area of the entire product is strictly required to have outstanding coplanarity.

5. The ultra-narrow board-to-board connector puts forward new requirements for the electroplating process. How to ensure that the product’s gold plating thickness and tinning effect does not climb tin, has become the most important problem in the miniaturization of the connector.

Jane Bull DIP Connector

6. The board-to-board connector can be constructed for simple machine circuit design. By providing an insulating wall on the bottom surface of the connector, the PCB board traces and metal terminals can be routed and wired on the bottom surface of the connector without touching, which is suitable for the miniaturization of the PCB board.

7. Assembling process guidance, with the development of the age, more and more micro-connectors are used, so when assembling, it is necessary to align the introduction point of view, and then press it hard, so as to prevent the product from being formed by dislocation and pressing damage

Post time: Sep-24-2020