In-depth analysis of the development status of board-to-board connectors

Currently, the board-to-board connectors used on mobile phones mainly have the following characteristics:

The first is “flexible”, flexible connection, and strong corrosion resistance; second, no welding, convenient installation, and no fire hazard, which saves space; but today’s board-to-board are ultra-low height , Two-piece type, the editor will focus on this point below; Finally, it has super environmental resistance, not only flexible, but also uses a “solid connection” with high contact reliability; of course, there are generally unlimited pipes and belts. The advantages of pressure sealing and convenient installation.

In order to improve the combined force of the socket and the plug, a simple locking mechanism is adopted in the fixed metal part and the contact part, which improves the combined force and makes the locking feel more pluggable. The connector can minimize the thickness of the product to achieve the purpose of connection, and this has led to more and more ultra-thin mobile phones on the market!

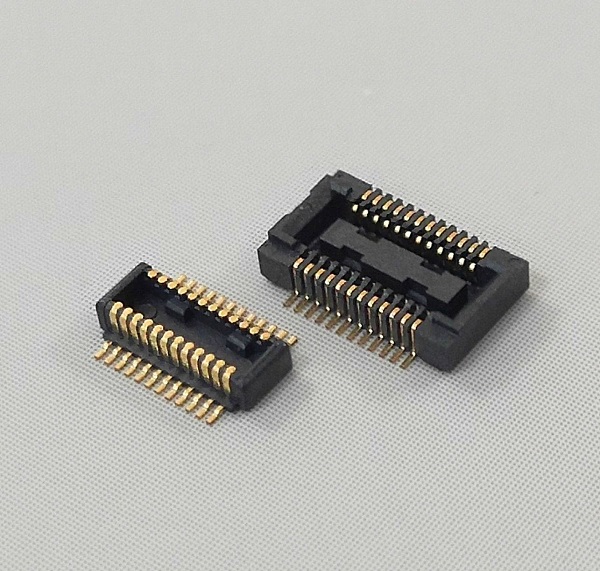

BOARD TO BOARD CONNECTORS PITCH :0.4MM(.016″) SMD H:1.5MM POSITION 10-100PIN

Narrow pitch board-to-board connector, 0.35mm pitch is currently mainly used in Apple mobile phones and domestic high-end models. Its application will be a major trend in the past two years. It has the smallest volume, the highest precision, and high performance. , But the requirements for patch and other supporting processes are higher. This is where many connector manufacturers need customer service most, otherwise the yield rate will be very low.

Today, when consumers have higher and higher requirements for product thickness and hand-feel experience, ultra-thin and ultra-narrow connectors put new requirements on the electroplating process. For products with a height of 0.6mm and a single product less than 0.4 mm in height, How to ensure that the thickness of the product’s gold plating and the effect of tinning does not climb over the tin has become the most critical issue in connector miniaturization. At present, the common practice in the industry is to block the path of the upper tin by peeling the gold-plated layer by laser to solve the problem of non-climbing tin. However, this technology has a disadvantage that when stripping gold, the laser will also damage the nickel-plated layer, thereby exposing the copper to the air, which will corrode and rust.

One thing to mention now is that board-to-board connectors can be constructed for simple machine circuit design. By installing an insulating wall on the bottom surface of the connector, the PC board traces and metal terminals can be routed and wired on the bottom surface of the connector without contact, which is very beneficial for the miniaturization of the PC board!

Post time: Aug-28-2020