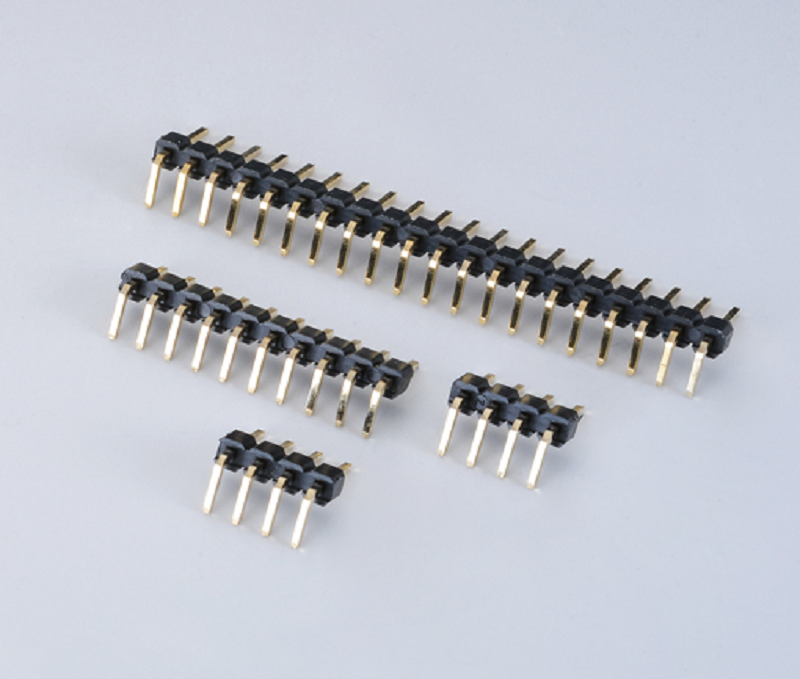

Hello everyone, I am the editor. One object needs to use a connector to connect with another object. Therefore, there are many board-to-board connectors around us, and everyone knows it better. Today, the editor will come to learn with you what technical characteristics the board-to-board connectors have, as follows:

1. First of all, “soft”, flexible connection, easy to install and easy to disassemble.

2. The ultra-low height of the board-to-board connector to achieve the purpose of reducing the thickness of the body

3. The contact structure has super environmental resistance. It is not only flexible, but also uses a “solid connection” with high contact reliability to improve the combined force of the socket and the plug. It is easy to use the fixed metal parts and the contact parts. Locking mechanism, while improving the combination force, makes it more plug-in and pull-out when locking

4. In order to meet the requirements of the SMT process, the terminal welding area of the entire product is strictly required to have good coplanarity

5. The ultra-narrow board-to-board connector puts forward new requirements for the electroplating process. How to ensure that the product’s gold plating thickness and tinning effect do not climb tin, has become an ultra-key problem in connector miniaturization

6. The board-to-board connector can be constructed for simple machine circuit design. By providing an insulating wall on the bottom surface of the connector, the PCB board trace and the metal terminal can be routed and wired on the bottom surface of the connector without contact, which is quite beneficial for the miniaturization of the PCB board.

7. Assembling process guidance. With the development of the times, there are more and more applications of micro-connectors. Therefore, when assembling, you must align the introduction angle and then press it down hard to avoid product damage caused by dislocation and pressing.

Post time: Oct-21-2020