OEM/ODM Supplier Pin Header Connectors - Factory For With Low Pvc Connection Pipe Production Line – Yuanyue Detail:

We’re committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Factory For With Low Pvc Connection Pipe Production Line, If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

We’re committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Pvc Connection Pipe Production Line, Pvc Pipe Production Line, Pvc Pipe Production Line With Low, We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

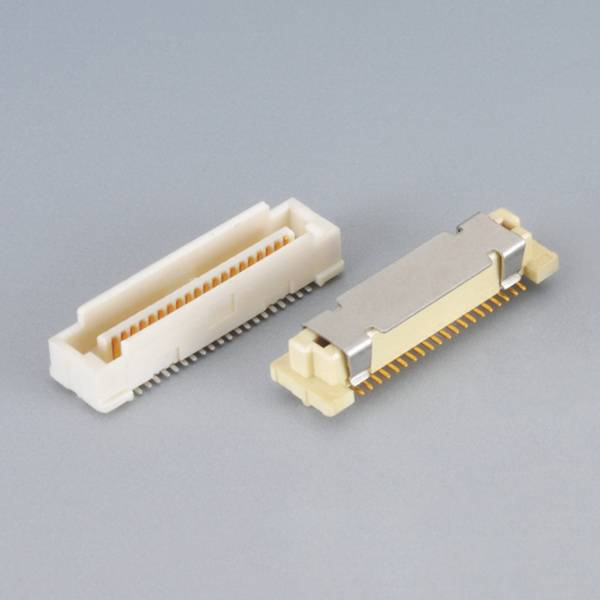

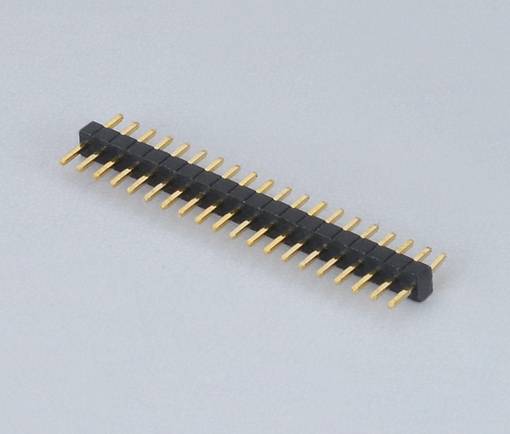

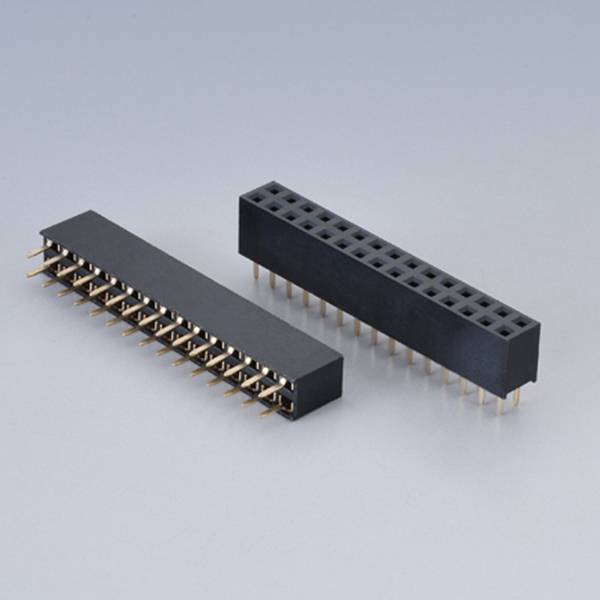

Electrical

Current Rating: 0.8A AC/DC

Voltage Rating:30V AC/DC

Contact Resistance:10mΩ MAX.

Physical

Insertion Force:44N MAX

Pullout Force:5N MIN

Insulator material: LCP/PA9T UL94V-0

Contact Material: Phosphor Bronze

Contact plated:selective Gold Plated

Shell: Brass with nickel plated

Operating Temperature: -20℃ ~ +85℃

soldering temperature:250℃±10℃/5Sec

Product detail pictures:

Related Product Guide:

Deadpool 2 Credits Scenes Are Canon, and They Almost Didn’t Happen | Cannon Cable

Creating UIs with Angular Material Design Components — SitePoint | Usb 2.0 A-M To Micro Usb Cable

OEM/ODM Supplier Pin Header Connectors - Factory For With Low Pvc Connection Pipe Production Line – Yuanyue, The product will supply to all over the world, such as: , , ,

————————— Company style —————————

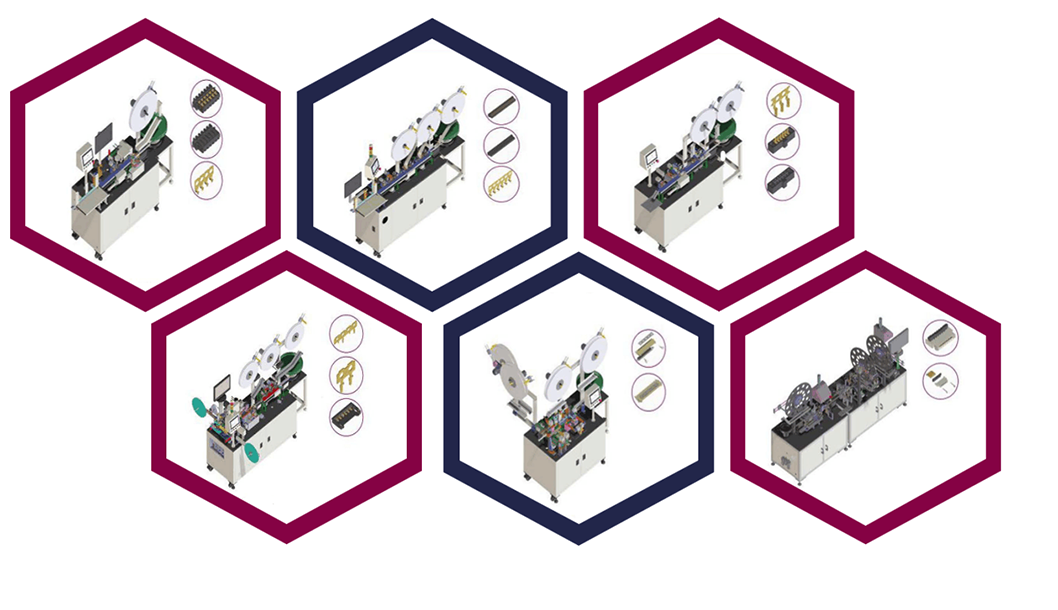

————————— Production line —————————

————————— Production equipment —————————

————————— Injection molding —————————

Injection molding workshop and experienced toolmaker can not only provide customized connector service,but also convenient for daily maintenance and repair of molds, which saves cost and increases efficiency for you. Plastic automatic feeding machine ensured injection sockets have perfect physical parameter. The injection molding machine with take off the mold automatically by mechanical arm improved the efficiency, of which hot runner system ensures the consistency of multi-cavity molding, improves the precision of plastic parts and greatly saves costs.

————————— Connectors —————————

All of our plastic materials are high temperature resistant materials,and most of them are from Taiwan and Japan.Automatic production & inspection & packaging machine guarantee high quality and short lead time. Thanks for automatic machine, our annual output reachs up to 15 million. Furthermore,we were devoted to development and production of alternatives since we founded. A large amount of R&D cost investment and engineer team with over 15 years experiences make us better in the field of small pitch and high precision connectors.

————————— Wire harness & Cable assembly —————————

We assist with cable and connector selection and assembly design solution, layout and manufacturing techniques.Our strength is internal electronic wire harness for various application,like Consumer Electronics,Computing,Medical,Automotive…etc, but more than 200 sets different forming molds can also meet your various need of cable assemblies. Wire cable extruder,automatic terminal crimping machine, digital wire cutting &stripping machine,USB automatic soldering machine,and automatic cable binding machine available to providing one-stop service for you.

Our Advantage :

- Automatic production & inspection & packaging machine ensured high quality and short lead time

- Material from Japan & Taiwan

- Annual Output up to 15 million

- Compliant with ROHS & REACH

- ISO 9001:2015 and IATF16949:2016 certified factory

- Mold workshop and toolmaker with more than 20 years experienced provide customized service

Testing equipment :

We will conduct strict product inspection before shipment.

5.Video Measuring Machine(YVM) 6.360° Degree Rotation Tester 7.Reflow Soldering Tester

5.Video Measuring Machine(YVM) 6.360° Degree Rotation Tester 7.Reflow Soldering Tester

Brine Spray Experiment Machine

High Voltage Tester

Insulation Tester

Contact Resistance Tester

DC Low resistance tester

Mitutoyo Height Gauge

Cable Conduction Tester

HD Coplanarity CCD Tester

Automatic Tester of Insertion And Extraction Force