Molweni nonke, ndingumhleli.Phantse kuzo zonke iimveliso ze-elektroniki kunye nezombane, izixhumi zebhodi ukuya kwibhodi ziye zaba yinto ebalulekileyo yokudibanisa amacandelo ahlukeneyo.Ubukho bekhonkco abukho kuphela ukuchithwa kunye nokudibanisa, kodwa kunye nomphathiswa wokubonelela ngoku kunye nomqondiso kwimveliso.

Kwinkqubo yokusebenzisa izihlanganisi, abaninzi abaqulunqi beenkqubo ze-elektroniki baye bafumana amava afanayo: ukusebenzisa izixhumi ezingabizi kakhulu, kwaye emva koko uhlawule ixabiso eliphezulu, nokuba uzisole.Ukukhetha okungalunganga kunye nokusetyenziswa kwezixhumi kunokubangela ukungaphumeleli kwenkqubo, ukukhumbula imveliso, iimeko zetyala lemveliso, umonakalo webhodi yesiphaluka, ukulungiswa kwakhona kunye nokulungiswa, oku kunokubangela ukulahlekelwa kweentengiso kunye nabathengi.Ke ngoko, xa uyila iimveliso zombane, kufuneka ukhethe isinxibelelanisi esifanelekileyo kwisixhobo sombane.Ngaphandle koko, imeko apho ibhodi encinci-to-ibhodi ikhonkco yenza yonke inkqubo ingasebenzi iya kuziva iphukile kakhulu.

Xa abantu bekhetha isinxibelelanisi, baya kuqala baqwalasele ulawulo lweendleko.Ezinye zikumgangatho ophezulu, uzinzo oluphezulu, kunye neempawu zoyilo lwesihlanganisi ngokwaso.Ukuze kuthintelwe abaqulunqi be-elektroniki ukuba bajonge ukubaluleka kweziqhagamshelo kwinkqubo yoyilo, ngenxa yelahleko encinci kunye nelahleko enkulu, abavelisi bebhodi ukuya kwibhodi yokudibanisa babonelela ngeengcebiso kuye wonke umntu:

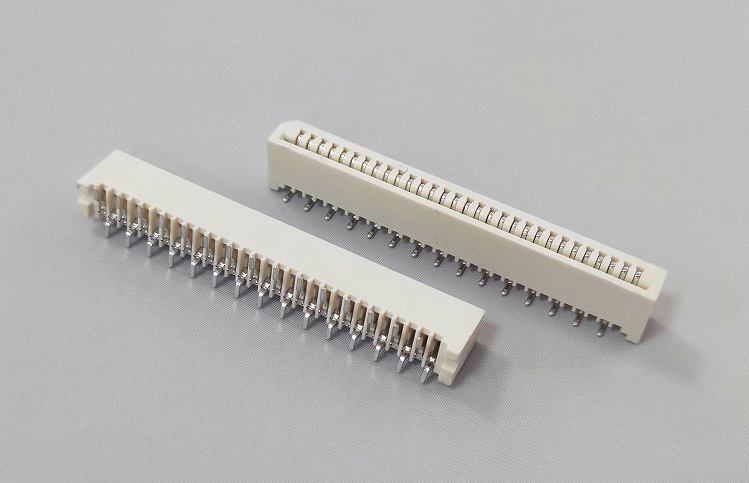

Okokuqala: umbono woyilo lwepali kabini.Kuluhlu lwesinxibelelanisi se-ERNI, ingcamango yokuyila i-double pole ihambelana kuyo yonke into.Ukuthetha ngokucacileyo, idizayini yeepali ezimbini inokuchazwa ngokuthi "iintaka ezimbini ngelitye elinye".Uyilo oluphuculweyo lwetheminali ukuziqhelanisa nokuhanjiswa komqondiso wesantya esiphezulu, ukubonelela ngonyamezelo oluphezulu lokuqhelaniswa.Ngokubhekiselele kwi-inductance, i-capacitance, i-impedance, njl., isakhiwo se-terminal ye-bar ye-double-bar sincinci kune-box-type ye-terminal structure ye-high-speed applications, kwaye ilungiselelwe ukufezekisa ukungaqhubeki kwe-ultra-encinci.Uyilo lweepali ezimbini luvumela izihlanganisi ezininzi ukuba zibe kwibhodi yesekethe enye ngaphandle kweplagi okanye iingxaki zesekethe emfutshane, kwaye akukho mfuneko yenani elikhulu leempawu kwikhonkco elilodwa.Umzila olula weepali eziphindwe kabini unokugcina indawo, wenze isinxibelelanisi sincinci, kwaye wenze lula ukufunyanwa kwezikhonkwane ze-solder.Umzekelo, beka i-12 ebhodini.Kwakhona kunciphisa iindleko zokusebenza kwakhona.Usetyenziso olusebenzayo olufana nesixhobo somsebenzisi wetheminali yonxibelelwano, njl.

Okwesibini: uyilo lwentaba yomgangatho ophezulu onamandla okugcina aphezulu.Kwiimveliso ze-SMT, kukholelwa ngokubanzi ukuba amandla okubamba ebhodini ahluphekile.Ngaba ugcino lwe-PCB lwezithintelo eziphezu komhlaba zingaphantsi kunelo lokupheliswa komngxuma?Impendulo kukuba: akunjalo.Ukuphuculwa koyilo kunokuphucula ngokufanelekileyo ukugcinwa kwePCB.Ukuba i-bracket ye-soldering, umngxuma (i-microhole) ye-surface pin pin, kunye ne-soldering pad enkulu, amandla okubamba anokuphuculwa.Ngapha koko, nezihlanganisi ze-I/O zinokusebenzisa izikhonkwane zokubeka umphezulu.Oku kunokufaniswa ngokucacileyo "nokuthatha iingcambu".Ngokomzekelo, ekuyilweni koomatshini be-X-ray, i-ultrasonic scanners, kunye ne-robotic Ethernet switches.

Okwesithathu: Uyilo olomeleleyo.Ukumisela ukuthembeka komdibaniso, ngelixa uvumela ukusetyenziswa kwezixhobo ze-flat crimping, i-pole plate igxininiswe kwigobolondo ukuphucula ukuqina, ukufezekisa inkqubo yokuvelisa engcono kunye nokwandisa umkhiqizo.Ukuyishwankathela ngegama elinye “kukuqina njengelitye.”Usetyenziso olukhethekileyo olunje nge-positron emission tomography scanners, iisistim ezifakwe kwiimoto zikaloliwe, njl.

Okwesine: umzobo ophakamileyo, uyilo lwesithuba esincinci.Ngokwenziwa kwe-miniaturization ye-automotive electronics kunye ne-electronics yabathengi, ingqikelelo yoyilo lwesithuba esiphezulu sangoku kunye nesincinci kufuneka sithathelwe ingqalelo.

Okwesihlanu: Akukho uyilo lwephini eligobileyo kwinkqubo yokuhlanganisa.Isitampu semveli siya kubangela ukugoba okanye ukuguqulwa kwezikhonkwane ngenxa yokulungiswa okungafanelekanga, kwaye inkqubo yokugoba iya kubangela ukuqhekeka kwe-capillary, engathandekiyo kwimveliso yexesha elide, kwaye iya kuchaphazela nokusebenza kwesiphaluka kunye neendleko.Kwaye i-ERNI isebenzisa ukunyathela ngokuthe ngqo kweekona, i-stamping terminals inokuphepha ukuqhekeka kwe-capillary okubangelwa yinkqubo yokugoba, kwaye uqinisekise uxhulumaniso olupheleleyo lwe-electromechanical.I-pin coplanarity yi-100%, kwaye ukunyamezela kulawulwa kwi-± 0.05mm.Uvavanyo lwe-100% ye-surface pin coplanarity test iqinisekisa ukuthembeka kwenkqubo yendibano yebhodi yesekethe, iqinisekisa i-soldering efanelekileyo, iphucula izinga lomgangatho wemveliso, kunye nokunciphisa iindleko.Kwaye uphucule ukuqina komdibaniso we-angle-angle ukukhusela umdibaniso ukuba wonakaliswe ngenxa yokusebenza okungafanelekanga.Igama elithi "ukungaqhawuki" lifanelekile kakhulu.Ilungele ngokukodwa ujongano lwemodyuli ye-Inkjet yomlawuli womshicileli we-inkjet.

Okwesithandathu: Uyilo oluphezulu lokutshixa.I-ERNI isebenzisa uyilo lokutshixa kabini ukuhlangabezana neemfuno ezahlukeneyo.Isitshixo esilungileyo siyilelwe usetyenziso olunamandla lokungcangcazela.Ilungele kakhulu izicelo zeemoto kunye ne-subway.Isitshixo sefriction siyilelwe usetyenziso lokungcangcazela ngokubanzi.Izitshixo eziphindwe kabini kunye ne-inshurensi yokhuseleko kabini iqinisekisa uqhagamshelo oluthembekileyo, kwaye akukho zixhobo zikhethekileyo zifunwayo kwi-site disassembly (ukulungisa/ukutshintshwa) kweentambo.Ifanelekile kuyilo lweemonitha, izibane zeemoto ze-LED, njl.

Izixhumi zebhodi ukuya kwibhodi zidlala indima ebalulekileyo ekuyilweni kwayo yonke inkqubo ye-elektroniki.Xa ukhetha amacandelo e-elektroniki, iinjineli kufuneka zinikele ingqalelo kungekuphela nje kwitekhnoloji ye-chip, kodwa kunye nokukhethwa kwamacandelo e-peripheral, ukwenzela ukuba inkqubo iqhube kakuhle., Dlala isiphumo sokuphindaphinda.

Ixesha lokuposa: Oct-11-2020