Uhlalutyo olunzulu lobume bophuhliso lwezixhumi zebhodi ukuya kwibhodi

Okwangoku, iziqhagamshelo zebhodi ukuya kwibhodi ezisetyenziswa kwiifowuni eziphathwayo ikakhulu zinezi mpawu zilandelayo:

Eyokuqala "i-flexible", uxhulumaniso oluguquguqukayo, kunye nokuxhathisa okuqinileyo kwe-corrosion;okwesibini, akukho welding, ufakelo olufanelekileyo, kwaye akukho ngozi yomlilo, egcina indawo;kodwa namhlanje ibhodi-to-ibhodi ukuphakama ultra-low , Uhlobo lweziqwenga ezimbini, umhleli uya kugxila kule ngongoma ingezantsi;Ekugqibeleni, inokumelana nokusingqongileyo okuphezulu, kungekhona nje ukuguquguquka, kodwa isebenzisa "uqhagamshelwano oluqinileyo" olunokuthembeka okuphezulu;kunjalo, kukho ngokubanzi imibhobho unlimited kunye namabhanti.Iingenelo zokutywinwa koxinzelelo kunye nofakelo olufanelekileyo.

Ukuze kuphuculwe amandla adibeneyo e-socket kunye neplagi, indlela yokutshixa elula iyamkelwa kwindawo yentsimbi esisigxina kunye nenxalenye yoqhagamshelwano, ephucula amandla adibeneyo kwaye yenza ukuba ukuvala kuzive kufakwe ngakumbi.Umdibaniso unokunciphisa ubukhulu bemveliso ukufezekisa injongo yokudibanisa, kwaye oku kuye kwakhokelela kwiifowuni eziphathwayo ezithe kratya kwiimarike!

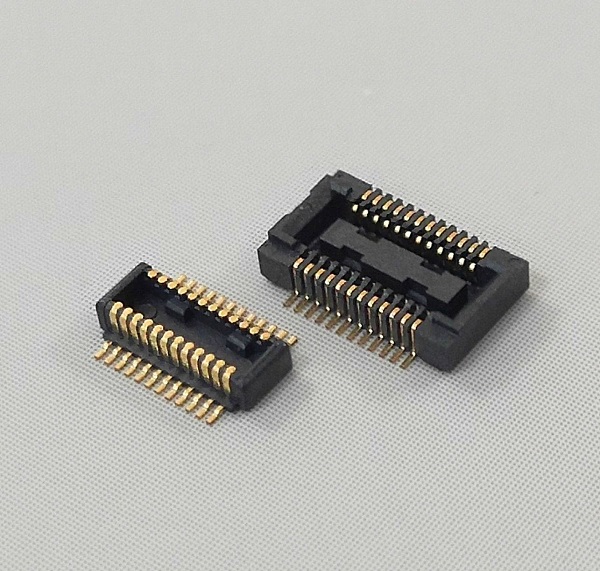

IZIQINISEKISO ZEBHODI UKUYA IBHODI :0.4MM(.016″) SMD H:1.5MM POSITION 10-100PIN

Umdibaniso webhodi ukuya kwibhodi emxinwa, i-0.35mm pitch okwangoku isetyenziswa kakhulu kwiifowuni ze-Apple kunye neemodeli zasekhaya eziphezulu.Ukusetyenziswa kwayo kuya kuba yinto ephambili kule minyaka mibini idlulileyo.Inomthamo omncinci, olona phawu luphezulu, kunye nokusebenza okuphezulu., Kodwa iimfuno zepatch kunye nezinye iinkqubo ezixhasayo ziphezulu.Apha kulapho abaninzi abavelisi bokudibanisa bafuna inkonzo yabathengi kakhulu, ngaphandle koko izinga lesivuno liya kuba liphantsi kakhulu.

Namhlanje, xa abathengi beneemfuno eziphezulu neziphezulu zokutyeba kwemveliso kunye namava okuziva ngesandla, iziqhagamshelo ze-ultra-thin kunye ne-ultra-narrow zibeka iimfuno ezintsha kwinkqubo ye-electroplating.Kwiimveliso ezinobude obuyi-0.6mm kunye nemveliso enye engaphantsi kwe-0.4 mm ubude, Ukuqinisekisa njani ukuba ubukhulu begolide yemveliso kunye nefuthe le-tinning ayinyuki phezu kwetoti ibe yeyona nto ibaluleke kakhulu kwi-miniaturization yokudibanisa. .Okwangoku, isenzo esiqhelekileyo kwishishini kukuthintela indlela ye-tin ephezulu ngokukhupha i-gold-plated layer by laser ukusombulula ingxaki ye-tin enganyuki.Nangona kunjalo, le teknoloji inento engalunganga yokuba xa kuhluthwa igolide, i-laser iya konakalisa umaleko we-nickel-plated, ngaloo ndlela iveze ubhedu emoyeni, oluya kugqwala kunye nokugqwala.

Into enye onokuyikhankanya ngoku kukuba iziqhagamshelo zebhodi ukuya kwibhodi zinokwakhelwa uyilo olulula lwesekethe yomatshini.Ngokufakela udonga lwe-insulating kwindawo ephantsi yesiqhagamshelo, ibhodi ye-PC ilandelela kunye nee-terminals zetsimbi zinokuhanjiswa kwaye zifakwe kwintambo kwindawo ephantsi yesiqhagamshelo ngaphandle koqhagamshelwano, oluyinzuzo kakhulu kwi-miniaturization yebhodi yePC!

Ixesha lokuposa: Aug-28-2020