Kwi-wire-to-board connector, isiseko se-insulating ye-connector sinikezelwa ngocingo olufumana i-groove ukwenzela ukuba ucingo olusetwe ngaphambili lubekwe kunye nokubeka,kunye ne-joint for butting kunye nekhonkco yangaphandle yenziwe kwelinye icala lesiseko sokukhusela, kwaye uninzi lwezihlanganisi zibonelelwa kwi-joint.Kukho iitheminali ezimbini zoqhagamshelwano ezibekwe macala onke, kwaye esinye isiphelo setheminali yoqhagamshelwano nganye sinikezelwe ngenxalenye yewelding edlula kwisiseko sokhuselo ukuya kwigroove yocingo olufumanayo kwaye luqhagamshelwe ngocingo olusetwe kwangaphambili, oluphawulwe ngokuba uninzi lweetheminali zoqhagamshelwano zikwindawo ethe tye. Ukumila kwe-U , Umzantsi we-terminal nganye yoqhagamshelwano unikwe indawo yewelding yomgama omde ebekwe kumphezulu ongaphakathi wocingo olufumana igroove, kwaye i-terminal yoqhagamshelwano nayo ibonelelwe ngenxalenye yoqhagamshelwano egobelwe phezulu kwaye ijike kwaye ijikeleze iperiphery. yesidibanisi.Uqhagamshelo lweWelding.Ngolu yilo lwesakhiwo, ukuphakama kwekhonkco kunokunciphisa ngokufanelekileyo, i-terminals yoqhagamshelwano igxininiswe ngokuqinileyo, indawo yoqhagamshelwano ilula ukuyiqonda, umphumo wokudibanisa ulungile, kwaye umphumo we-impedance ephantsi unokufumaneka.

Xa ibhodi yesekethe eprintiweyo kwinkqubo kunye nezixhobo zombane zifumana / zihambisa amandla okuvelisa umqondiso, kufuneka zixhunywe ngaphandle kwe-substrate.Kwiimeko ezininzi, kukho umgama othile phakathi kwebhodi yesekethe eprintiweyo kunye ne-substrate, efuna ukuba iingcingo zidibanise.Ukudibanisa umgama omde kunokufezekiswa ngeengcingo ze-soldering kwi-substrate.Nangona kunjalo, ukuqwalaselwa kokusebenza, ii-multi-pin wire-to-board connectors zidla ngokusetyenziselwa ukudibanisa.

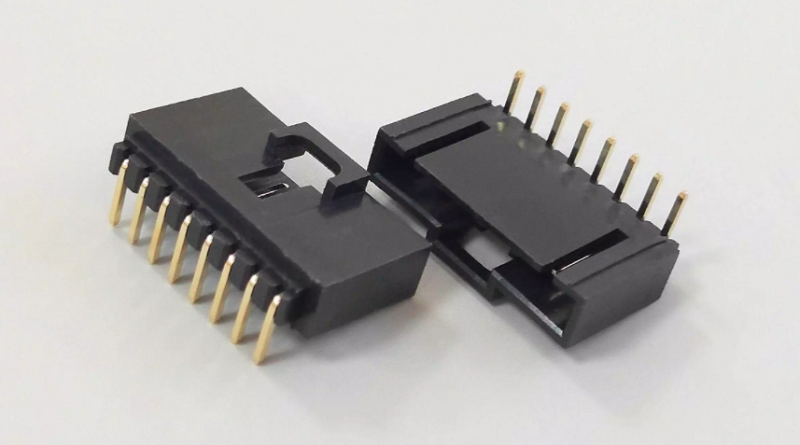

Ubume be-wire-to-board connector bulula kakhulu: faka i-electrodes (abafowunelwa) kwigobolondo (igobolondo yeplastiki).Kukho iindidi ezimbini zabafowunelwa: intonga okanye itshiphu "iplagi" kunye ne "socket".Gcoba iplagi ngokupheleleyo kwi-socket kwaye uyigubungele ukuze ufezekise "ukuhambelana".Ngokuqhelekileyo, i-socket ixhunyiwe kwintambo kwaye iplagi ixhunyiwe kwi-substrate, kodwa oku kunokutshintshwa ngokuxhomekeke ekusebenziseni.Ukudityaniswa kweengcingo kunye nabafowunelwa ngokuqhelekileyo kufezekiswa ngokusebenzisa iteknoloji "yoxinzelelo lwe-pressure", ezifana ne-crimp terminals.Ungasebenzisa kwakhona "i-welding yoxinzelelo" ukudibanisa iingcingo kunye nabafowunelwa.Itekhnoloji ye-welding yoxinzelelo isetyenziselwa ukudityaniswa kwangoku okuphantsi, ukuvumela uxhulumaniso olupheleleyo ngokudibanisa iingcingo ezifakwe kwi-insulated kubafowunelwa.Nangona le ndlela ifanelekile, ukuqina kunokuncipha.Ezi teknoloji zimbini zingentla zinokuphepha ukushisa okubangelwa yi-teknoloji ye-soldering kunye nokukhusela ukudibanisa kumonakalo.Ukongezelela, ekubeni indawo yokudibanisa i-airtight ayibonakali emoyeni, uxhumano lunokugcinwa luzinzile.

Ixesha lokuposa: Aug-19-2020