Molweni nonke, ndingumhleli.Into enye idinga ukusebenzisa isinxibelelanisi ukudibanisa nenye into, ngoko kukho iziqhagamshelo ezininzi zebhodi ukuya kwibhodi ezisingqongileyo, kwaye wonke umntu uyazi ngcono.Namhlanje, ndiza kuza kwaye ndifunde kunye nawe ukuba zeziphi iimpawu zobuchwepheshe izixhumi zebhodi ukuya kwibhodi, ngolu hlobo lulandelayo:

1. Okokuqala, "i-soft", uxhulumaniso oluguquguqukayo, ukufakela okufanelekileyo, kunye nokuchithwa okufanelekileyo.

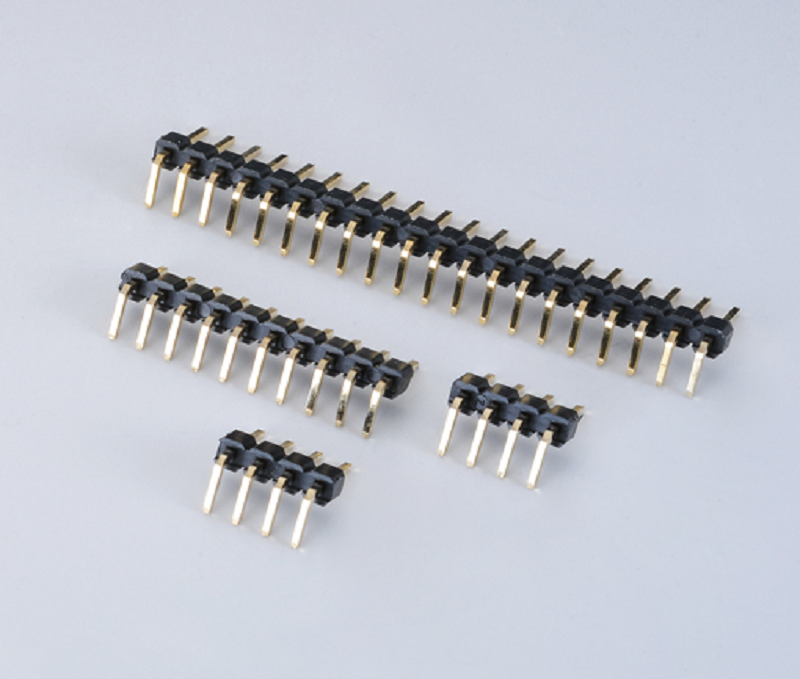

2. Ubude obuphantsi kakhulu bebhodi ukuya kwibhodi yokudibanisa ukunciphisa ubukhulu bomzimba

3. Isakhiwo soqhagamshelwano sinokuchasana okuphezulu kokusingqongileyo.Akukona nje ukuguquguquka, kodwa kwakhona yamkela "uxhulumaniso oluqinileyo" kunye nokuthembeka koqhagamshelwano oluphezulu ukuphucula amandla adibeneyo wesokhethi kunye neplagi.Kulula ukusebenzisa iindawo zetsimbi ezisisigxina kunye neendawo zoqhagamshelwano.Indlela yokutshixa, ngelixa iphucula amandla okudibanisa, iyenza iplagi ngakumbi kwaye ikhuphe iplagi xa itshixiwe

4. Ukuze kuhlangatyezwane neemfuno zenkqubo ye-SMT, indawo yokuwelda i-terminal yayo yonke imveliso ifuneka ngokungqongqo ukuba ibe ne-coplanarity elungileyo.

5. I-ultra-namxinano yebhodi-to-ibhodi isixhumi sibeka phambili iimfuno ezintsha zenkqubo ye-electroplating.Ukuqinisekisa njani ukuba ubukhulu begolide yemveliso kunye nefuthe le-tinning ayinyuki i-tin, ibe yingxaki enkulu kwi-miniaturization yesinxibelelanisi.

6. Ibhodi-to-ibhodi isinxibelelanisi inokwakhelwa uyilo olulula umatshini isekethe.Ngokubonelela ngodonga olukhuselayo kumphezulu osezantsi wesiqhagamshelo, umkhondo webhodi yePCB kunye netheminali yentsimbi inokuhanjiswa kwaye ifakwe intambo kumphezulu ongezantsi wesiqhagamshelo ngaphandle koqhagamshelwano, nto leyo eluncedo kakhulu kwi-miniaturization yebhodi yePCB.

7. Isikhokelo senkqubo yokuhlanganisa.Ngophuhliso lwamaxesha, kukho usetyenziso oluninzi nangakumbi lwe-micro-connectors.Ke ngoko, xa udityaniswa, kufuneka ulungelelanise i-angle yentshayelelo kwaye emva koko uyicinezele phantsi kanzima ukunqanda umonakalo wemveliso obangelwa kukuchithwa kunye nokucinezela.

Ixesha lokuposa: Oct-11-2020