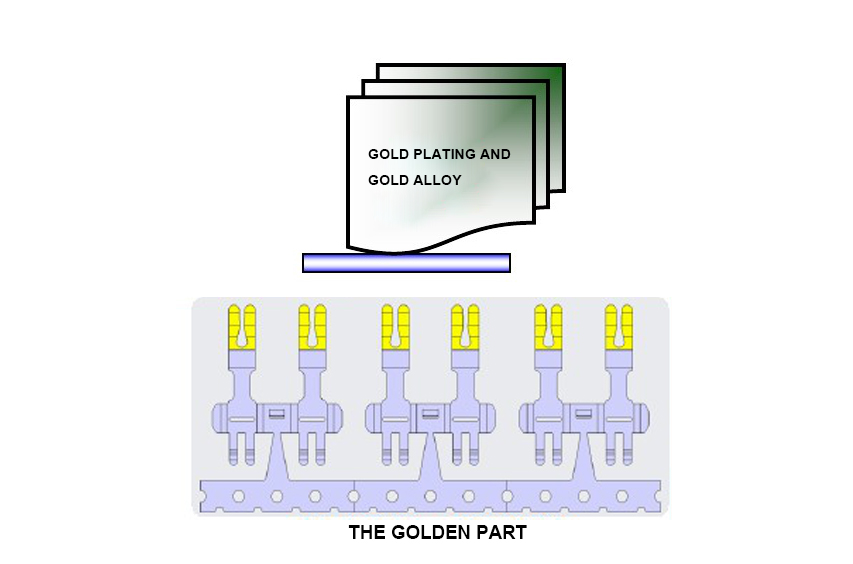

Ukwethulwa kokufakwa kwegolide

1.Igolide insimbi eyigugu eyigolide ethambile futhi kulula ukuyipholisha.

I-2.Igolide inokuqina okuhle kwamakhemikhali, ayincibiliki kuma-asidi ajwayelekile, ancibilika kuphela ku-aqua regia

I-3.I-Gold coating inokumelana nokugqwala okuqinile nokumelana okuhle nokuguquguquka

4.I-Gold Plating inemibala ehlukahlukene, futhi isetshenziselwa izigqoko zokuhlobisa ezibizayo

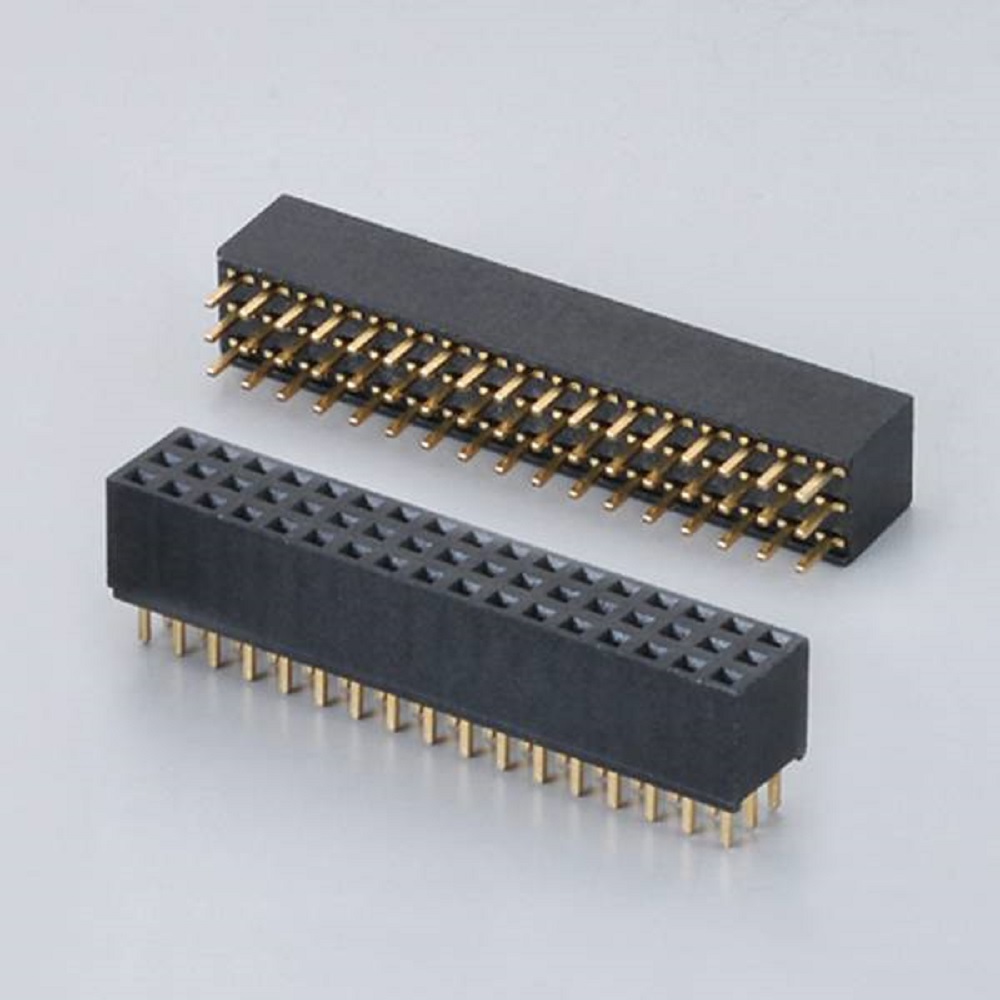

INHLOKO YESIFAZANE:2.0MM(.047″) UROW OCATHUSI OQINILE 180°

I-5.Gold inokumelana okuphansi kokuxhumana kanye ne-conductivity enhle, futhi ivame ukusetshenziswa ezimweni zokuxhumana ezishelelayo.

I-6.I-Gold Plating ilula ukushisela futhi inokumelana okuhle kwezinga lokushisa,ukusebenza okuthile kokumelana nokugqoka, kepha qaphela, akulona igolide eliwugqinsi elilula kakhulu ukushisela, ngokuphambene nalokho, ungqimba lwegolide 3-5 ų ° umphumela wokushisela. kungcono kakhulu.

7.Ukwengezwa kwethusi egolideni kunomphumela omncane ebukhuni, kodwa ukungezwa kwe-nickel engu-10% kunomphumela omkhulu ebukhuni.Ngaphandle kwalokho, i-au-NI alloy inokuqina okuphezulu.

8.Umoya ongemuhle wegolide, igolide eliphansi lizoba ne-diffusion phenomenon. Ngokujwayelekile ngesisekelo se-nickel, shiya ukuze uvimbele ukusakazeka kwegolide phansi.

9.Igolide linendawo encibilikayo ephansi futhi lincibilika kalula ethini ngesikhathi sokushiselwa kwe-nickel, okuholela ekwakhekeni kwezinhlanganisela ze-AU-SN kanye nokwakheka kwegolide elibukhali.

10. Ikhono lokuqeda ukugqwala lengxubevange yethusi yokuqala elicwebezelayo ku-nickel ų 50 ° lihle kakhulu, kodwa inqobo nje uma liku-nickel - ukunamathisela ungqimba lombhalo, ikhono lokumelana nokugqwala liphansi kakhulu. Isizathu siwukuthi umehluko ongaba khona phakathi kwegolide negolide. i-nickel inkulu kakhulu, ebangela ukusabela kokugqwala okusheshayo kwe-Galliani.Ukuhlolwa kwesifutho sikasawoti kufakazela ukuthi lo mbono ulungile.Ekuqaleni, i-nickel ngaphandle kokucwecwa kwegolide elincanyana ingahlala amahora angama-72, kuyilapho i-nickel enegolide elicwengekileyo ayikwazi ukuhlala amahora angama-48.

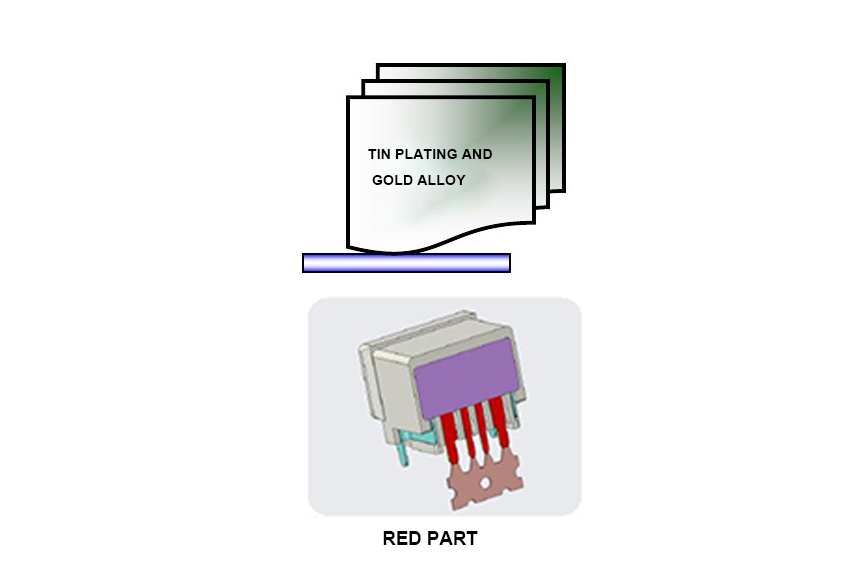

Ukwethulwa kwe-tin electroplating

1.Ithini linokubukeka okumhlophe okusasiliva.

2.Ithini liyakwazi ukumelana nokugqwala, alikwazi ukumelana nombala, alinabo ubuthi, kulula ukulishisela futhi libhodlokile

I-3.I-tin enamathela inokuqina okuphezulu kwamakhemikhali

4.I-electrical conductivity of tin coating inhle, kulula ukuyishisela, futhi imvamisa ithatha indawo yethayela lesiliva.

5.I-incoating inesimo se-tin fever, kodwa hhayi nge-bismuth, i-antimony alloy\

6.I-tin enamathela ekushiseni okuphezulu, okumanzi, izimo ezivaliwe zizokhiqiza amadevu ethini.

7.Iphuzu lokuncibilika le-tin-lead alloy liphansi kunomthofu omsulwa kanye nethini elihlanzekile, i-porosity yayo kanye nokushisela kungcono kunensimbi eyodwa, kuthayela elihlanzekile inqobo nje uma ukwengezwa komthofu ongu-2-3%, akulula khiqiza i-whisker ye-tin, ngakho-ke i-tin-lead alloy coating iyona ebaluleke kakhulu enamathelayo ethengiswayo ezingxenyeni ze-elekthronikhi, ingangena esikhundleni se-coating yesiliva ngaphakathi kwebanga elithile.

I-8.Ivame ukusetshenziselwa izinto zokushisela futhi ingasetshenziselwa ukuhlanganisa amandla amakhulu okuxhumana.

Isikhathi sokuthumela: Jul-22-2020