Sanibonani nonke, yimina mhleli.Cishe kuyo yonke imikhiqizo ye-elekthronikhi nekagesi, izixhumi zebhodi ukuya ebhodini seziyinto ebalulekile yokuxhuma izingxenye ezihlukahlukene.Ukuba khona kwesixhumi akukona nje ukuqaqa nokuxhumana, kodwa futhi kusithwali sokuhlinzeka okwamanje kanye nesignali kumkhiqizo.

Enkambweni yokusebenzisa izixhumi, abaklami abaningi bezinhlelo ze-elekthronikhi baye baba nesipiliyoni esifanayo: ukusebenzisa izixhumi ezishibhile, bese bekhokha inani eliphakeme, baze bazisole.Ukukhetha okungalungile kanye nokusetshenziswa kwezixhumi kungabangela ukwehluleka kwesistimu, ukukhunjulwa komkhiqizo, amacala esikweletu somkhiqizo, ukulimala kwebhodi lesifunda, ukusetshenzwa kabusha nokulungiswa, okungabangela ukulahlekelwa kokuthengisa namakhasimende.Ngakho-ke, lapho uklama imikhiqizo ye-elekthronikhi, kufanele ukhethe isixhumi esifanele idivayisi kagesi.Uma kungenjalo, isimo lapho isixhumi esincane sebhodi kuya ebhodini senza lonke uhlelo lungasebenzi sizozizwa siphukile kakhulu.

Uma abantu bekhetha isixhumi, bazoqale bacabangele ukulawula izindleko.Ezinye ziyikhwalithi ephezulu, ukuzinza okuphezulu, nezici zokuklama zesixhumi ngokwaso.Ukuze uvimbele abaklami be-elekthronikhi ukuthi bangabukeli phansi ukubaluleka kwezixhumi enqubweni yokuklama, ngenxa yokulahlekelwa okuncane nokulahlekelwa okukhulu, abakhiqizi bezixhumi zebhodi ukuya ebhodini banikeza iziphakamiso ezithile kuwo wonke umuntu:

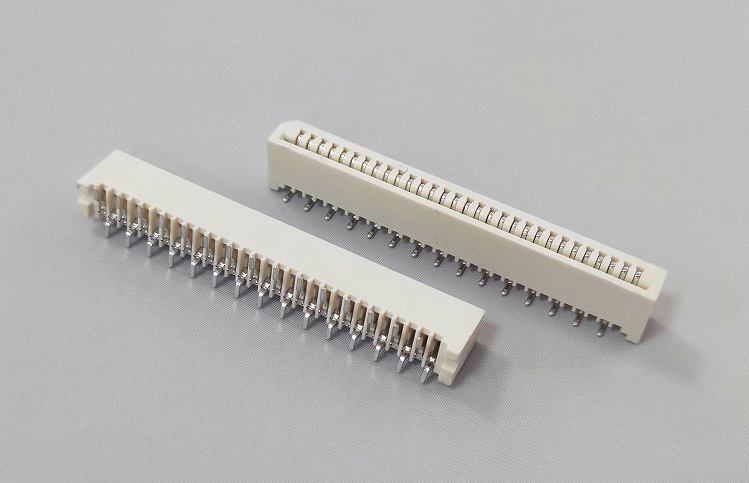

Okokuqala: umbono we-double pole design.Ochungechungeni lwesixhumi se-ERNI, umbono we-double pole design uyavumelana kulo lonke.Ukukhuluma ngokucacile, umklamo we-double pole ungachazwa ngokuthi "izinyoni ezimbili ngetshe elilodwa".Idizayini yetheminali ethuthukisiwe ukuze ivumelane nokudluliswa kwesignali enesivinini esikhulu, inikeze ukubekezelela ukuma okuphakeme.Mayelana ne-inductance, capacitance, impedance, njll., isakhiwo setheminali yamabha amabili sincane kunesakhiwo setheminali yohlobo lwebhokisi lezinhlelo zokusebenza ezinesivinini esikhulu, futhi sithuthukiswe ukuze kuzuzwe ukungaqhubeki okuncane kakhulu.I-dual-pole design ivumela izixhumi eziningi ukuba zibe ebhodini lesifunda elilodwa ngaphandle kokuxhuma noma izinkinga zesifunda esifushane, futhi asikho isidingo senombolo enkulu yamasignali kusixhumi esisodwa.Umzila olula wezigxobo ezimbili ungagcina isikhala, wenze isixhumi sibe sincane, futhi wenze lula ukutholwa kwezikhonkwane ze-solder.Isibonelo, beka i-12 ebhodini.Iphinde yehlise izindleko zokulungisa kabusha.Izinhlelo zokusebenza ezisebenzayo ezifana netheminali yomsebenzisi wetheminali yezokuxhumana, njll.

Okwesibili: Idizayini ye-Surface Mount enamandla amakhulu okugcina.Ngemikhiqizo ye-SMT, ngokuvamile kukholakala ukuthi amandla okubamba ebhodini awalungile.Ingabe amandla okugcina e-PCB okunqanyulwa kwe-surface mount aphansi kunalawo okunqanyulwa kwembobo?Impendulo ithi: akunjalo.Ukuthuthukiswa kwedizayini kungathuthukisa ngempumelelo ukugcinwa kwe-PCB.Uma i-soldering bracket, imbobo (i-microhole) ye-surface pin pin, kanye ne-soldering pad enkulu, amandla okubamba angathuthukiswa.Eqinisweni, ngisho nezixhumi ze-I/O zingasebenzisa izikhonkwane zokukhweza ngaphezulu.Lokhu kungafaniswa ngokucacile nokuthi "thatha izimpande".Isibonelo, ekwakhiweni kwemishini ye-X-ray, izikena ze-ultrasonic, namaswishi e-Ethernet yerobhothi.

Okwesithathu: Idizayini eqinile.Ukuze unqume ukwethembeka kwesixhumi, kuyilapho kuvumela ukusetshenziswa kwamathuluzi okugoqa ayisicaba, ipuleti le-pole ligxilile kugobolondo ukuze kuthuthukiswe ukuqina, ukufeza inqubo engcono yokukhiqiza nokwandisa okukhiphayo.Ukukuhlanganisa ngegama elilodwa “kuqina njengedwala.”Izinhlelo zokusebenza eziqondile ezifana nezikena ze-positron emission tomography, amasistimu ashumekiwe emoto kaloliwe, njll.

Okwesine: yamanje ephezulu, idizayini yesikhala esincane.Ngokwenziwa okuncane kogesi wezimoto kanye nogesi wabathengi, umqondo wokuklama wesikhala esiphezulu samanje nesincane udinga ukucatshangelwa.

Okwesihlanu: Ayikho idizayini yephinikhodi egobile enqubweni yokuhlanganisa.Ukugxiviza kwendabuko kuzodala ukugoba noma ukukhubazeka kwezikhonkwane ngenxa yokucubungula okungalungile, futhi inqubo yokugoba izobangela ukuqhekeka kwe-capillary, okungafuneki kumkhiqizo wesikhathi eside, futhi kuzothinta nokusebenza kwesifunda kanye nezindleko.Futhi i-ERNI isebenzisa ukunyathela okuqondile kwamakhona, amatheminali okugxiviza angagwema imifantu ye-capillary ebangelwa inqubo yokugoba, futhi uqinisekise uxhumano oluphelele lwe-electromechanical.I-pin coplanarity ingu-100%, futhi ukubekezelelana kulawulwa ku-±0.05mm.Ukuhlolwa kwe-surface pin coplanarity engu-100% kuqinisekisa ukwethembeka kwenqubo yokuhlanganisa ibhodi lesifunda, kuqinisekisa ukusoda okuhle, kuthuthukisa izinga lekhwalithi yomkhiqizo, futhi kunciphisa izindleko.Futhi uthuthukise ukuqina kwesixhumi se-engeli engakwesokudla ukuze uvimbele isixhumi ukuthi singalimali ngenxa yokusebenza okungalungile.Igama elithi "ukunganqamuki" lifaneleka kakhulu.Ifaneleka ngokukhethekile isixhumi esibonakalayo semojula ye-InterfaceModule yesilawuli sephrinta ye-inkjet.

Okwesithupha: Idizayini yokukhiya ethuthukisiwe.I-ERNI isebenzisa idizayini yokukhiya kabili ukuze ihlangabezane nezidingo ezahlukene.Ilokhi ephozithivu yakhelwe izinhlelo zokusebenza ezinamandla zokudlidliza.Ilungele kakhulu izinhlelo zokusebenza zezimoto nezangaphansi komhlaba.Ilokhi yefriction yakhelwe izinhlelo zokusebenza zokudlidliza ezijwayelekile.Izingidi ezimbili nomshwalense wokuphepha okabili ziqinisekisa ukuxhumana okuthembekile, futhi awekho amathuluzi akhethekile adingekayo ukuze kuhlakazwe izintambo (ukulungisa/ukushintsha) endaweni.Ifanele ukuklanywa kwama-monitor, amalambu emoto e-LED, njll.

Izixhumi zebhodi ukuya ebhodini zidlala indima ebalulekile ekwakhiweni kwalo lonke uhlelo lwe-elekthronikhi.Lapho ukhetha izingxenye ze-elekthronikhi, onjiniyela kudingeka banganaki kuphela ubuchwepheshe be-chip, kodwa futhi nokukhethwa kwezingxenye ze-peripheral, ukuze benze uhlelo lusebenze kahle., Dlala umphumela wokuphindaphinda.

Isikhathi sokuthumela: Oct-11-2020