Sanibonani nonke, yimina mhleli.Kunezinhlobo eziningi zezixhumi zikagesi, okuhlanganisa nezixhumi ze-bTB, kodwa inqubo yokukhiqiza iyafana, ngokuvamile ihlukaniswa ngezigaba ezine ezilandelayo:

1. Ukugxiviza

Inqubo yokukhiqiza yezixhumi zikagesi ngokuvamile iqala ngezikhonkwane zokugxiviza.Ngomshini omkhulu wokubhoboza onesivinini esikhulu, isixhumi se-elekthronikhi (iphinikhodi) sishaywa ngomucu omncane wensimbi.Omunye umkhawulo webhande elikhulu lensimbi elihlanganisiwe lithunyelwa ekupheleni komshini wokubhoboza, kanti elinye lidluliswa ku-hydraulic worktable yomshini wokubhoboza ukuze ulinyazwe esondweni elinyakazayo, futhi ibhande lensimbi likhishwa isondo elinyakazayo futhi umkhiqizo oqediwe uyakhishwa.

2. I-Electroplating

Izikhonkwane zokuxhuma kufanele zithunyelwe esigabeni se-electroplating ngemva kokuphothula isitembu.Kulesi sigaba, indawo yokuxhumana kagesi yesixhumi izobe ihlanganiswe nezingubo ezihlukahlukene zensimbi.Ikilasi lezinkinga ezifana nesiteji sokugxiviza, njengokusonteka, ukuchopha noma ukuwohloka kwezikhonkwane, nalo lizovela lapho izikhonkwane ezinezigxivizo zifakwa emshinini wokugcwalisa ugesi.Ngokusebenzisa amasu achazwe kulesi sihloko, lolu hlobo lwesici sekhwalithi lungatholakala kalula.

Kodwa-ke, kubahlinzeki abaningi besistimu yombono womshini, iziphambeko eziningi zekhwalithi kunqubo ye-electroplating ziseyingxenye "yendawo evinjelwe" yesistimu yokuhlola.Abakhiqizi bezixhumi ze-elekthronikhi bathemba ukuthi isistimu yokuhlola ingathola iziphambeko ezihlukahlukene ezingaguquki njengemihuzuko emincane namaphinifa endaweni yokucwenga yezikhonkwane zokuxhuma.Nakuba lezi zinkinga kulula ukuzibona kweminye imikhiqizo (njenge-aluminium can bottoms noma ezinye izindawo eziyisicaba);nokho, ngenxa yokwakheka okungavamile kanye ne-angular surface yezixhumi eziningi ze-elekthronikhi, amasistimu okuhlola okubukwayo anzima ukuthola Isithombe esidingekayo ukukhomba lezi zinkinga ezicashile.

Ngenxa yokuthi ezinye izinhlobo zamaphini zidinga ukunameka ngezendlalelo eziningi zensimbi, abakhiqizi futhi bathemba ukuthi isistimu yokuthola ingahlukanisa izimbotshana zensimbi ukuze kuqinisekiswe ukuthi zisendaweni yini nokuthi izilinganiso zilungile.Lona umsebenzi onzima kakhulu wezinhlelo zombono ezisebenzisa amakhamera amnyama namhlophe, ngoba amazinga ampunga ezithombe zezingubo zensimbi ezahlukene ayafana.Nakuba ikhamera yesistimu yombono wombala ingakwazi ukuhlukanisa ngempumelelo lezi zimbotshana zensimbi ezihlukene, inkinga yokukhanya okunzima isekhona ngenxa ye-engeli engavamile kanye nokubonakaliswa kwendawo yokumboza.

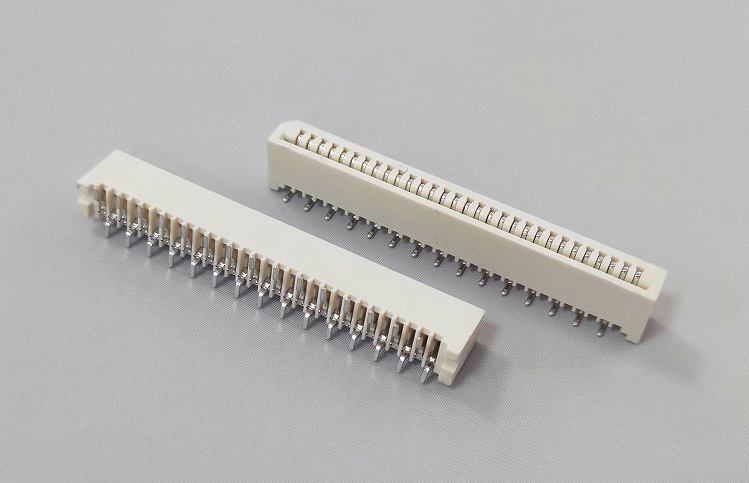

I-YFC10L SERIES FFC/FPC I-PITCH YOKUXHUMANISA:1.0MM(.039″) UHLOBO OKUQONDILE LE-SMD OKUNGEYO-ZIF

3. Umjovo

Isihlalo sebhokisi lepulasitiki lesixhumi se-elekthronikhi senziwa esiteji sokubumba umjovo.Inqubo evamile ukujova ipulasitiki encibilikisiwe efilimini yensimbi ye-fetus, bese uyipholisa ngokushesha ukuze yakheke.Lapho ipulasitiki encibilikisiwe ihluleka ukugcwalisa ngokuphelele ulwelwesi lwengane, lokho okubizwa ngokuthi “ukuvuza?”(Amashothi Amafushane) kwenzeka, okuyisici esijwayelekile esidinga ukutholwa esigabeni sokubumba umjovo.Okunye ukukhubazeka kuhlanganisa ukugcwaliswa noma ukuvinjelwa ingxenye yesokhethi (lezi Isokhethi kufanele igcinwe ihlanzekile futhi ivuliwe ukuze ixhunywe ngendlela efanele kuphini ngesikhathi somhlangano wokugcina).Ngenxa yokuthi ukusetshenziswa kwe-backlight kungabona kalula isihlalo sebhokisi esilahlekile kanye nokuvinjelwa kwesokhethi, kusetshenziselwa umbono womshini wokuhlolwa kwekhwalithi ngemuva kokubunjwa komjovo.Uhlelo lulula futhi kulula ukulusebenzisa

4. Umhlangano

Isigaba sokugcina sokukhiqiza isixhumi se-elekthronikhi siqedwa ukuhlanganiswa komkhiqizo.Kunezindlela ezimbili zokuxhuma izikhonkwane ze-electroplated esihlalweni sebhokisi lomjovo: ukukhwelana ngakunye noma ukukhwelana okuhlangene.Ukukhwelana ngokwehlukana kusho ukufaka iphinikhodi eyodwa ngesikhathi;ukuhlangana okuhlanganisiwe kusho ukuxhuma izikhonkwane eziningi nesihlalo sebhokisi ngesikhathi esisodwa.Kungakhathaliseki ukuthi iyiphi indlela yokuxhuma eyamukelwayo, umenzi udinga ukuthi zonke izikhonkwane zihlolwe ukuthi azikho futhi zimi kanjani ngendlela efanele ngesikhathi sokuhlanganisa;olunye uhlobo lomsebenzi wokuhlola ovamile luhlobene nesilinganiso sebanga phakathi kwezindawo zokukhwelana zesixhumi.

Njengesiteji sokugxiviza, ukuhlanganiswa kwesixhumi nakho kubangela inselele ohlelweni lokuhlola oluzenzakalelayo mayelana nesivinini sokuhlola.Nakuba imigqa eminingi yokuhlanganisa inesiqephu esisodwa noma ezimbili ngomzuzwana, isistimu yombono ngokuvamile idinga ukuqedela izinto eziningi zokuhlola ezihlukene zesixhumi ngasinye esidlula kukhamera.Ngakho-ke, isivinini sokuthola sesiphinde saba inkomba ebalulekile yokusebenza kwesistimu.

Ngemuva kokuthi umhlangano usuqediwe, izilinganiso zangaphandle zesixhumi zikhulu kakhulu kunokubekezelela kwe-dimensional okuvumelekile kwephinikhodi eyodwa ngohlelo lobukhulu.Lokhu futhi kuletha enye inkinga ohlelweni lokuhlola okubukwayo.Isibonelo: ezinye izihlalo zebhokisi lesixhumi zingaphezu kwefithi elilodwa ngosayizi futhi zinamakhulu amaphini, futhi ukunemba kokutholwa kwendawo ngayinye yephini kufanele kube phakathi kwezinkulungwane ezimbalwa zamayintshi.Ngokusobala, isixhumi esinobude obuyimitha elilodwa asikwazi ukutholwa esithombeni, futhi isistimu yokuhlola ebonakalayo ingathola kuphela inani elilinganiselwe lekhwalithi yephinikhodi endaweni encane yokubuka ngesikhathi.Kunezindlela ezimbili zokuqedela ukuhlolwa kwesixhumi sonke: ukusebenzisa amakhamera amaningi (ukwandisa izindleko zesistimu);noma icupha ikhamera ngokuqhubekayo lapho isixhumi sidlula phambi kwelensi, futhi isistimu yombono "ithunga" izithombe zohlaka olulodwa ezishuthwe ngokuqhubekayo , Ukwahlulela ukuthi ikhwalithi yaso sonke isixhumi sifanelekile yini.Indlela yakamuva iyindlela yokuhlola evame ukwamukelwa uhlelo lokuhlola okubukwayo lwe-PPT ngemva kokuba isixhumi sihlanganisiwe.

Isikhathi sokuthumela: Sep-24-2020